|

| |||

|

Bandsaw

| ||||

|

| |||

|

Bandsaw

| ||||

| Caster Base | Circle Jig | Resaw Guide | Jet 10" Bandsaw |

| Resaw Guide 2 | 6" Updraft Valve | Fence Corrosion | Blade Radius |

Sold my JWBS-14DXPRO last Thursday 09/27/18 (I felt almost naked without a bandsaw in the shop) but my new JWBS-14SFX arrived the next day, Friday 09/28/18.

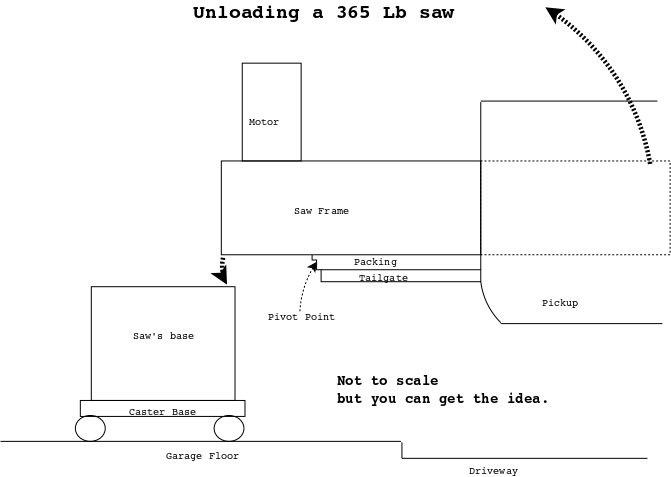

Betty and I unloaded the Jet 14SFX Saturday morning.

Robert, at the Garland Tx Rockler store, was nice enough to make sure the base was toward the tailgate.

Removed most of the small parts and packing, especially at the saw's bottom end (at the tail gate).

I put the saw's base (shipped in a separate box) on my caster base.

Scooted the saw until just before it wanted to start tipping over, motor was just a little past the end of the tailgate (the balance point).

Lined up the saw's base so the it was under the saw.

Betty held the caster base (casters locked), and I got in the bed and tilted the saw onto it's base.

When you do this, you have to have the pickup far enough into the garage that the saw's top will clear the garage door as it is tilted up.

Position the saw's base so the saw will come down on it's top near the edge.

Two old folks unloading a 285 lb. saw, no sweat (AKA: Duck Soup).

I put a Timberwolf 116" 3/4 X 2/3 VPC blade on the 14SFX, and it saws great, easy to line up and the saw is much more powerful.

But, There are two things I don't particularly care for about the JWBS-14SFX's design: both relate to the dust collection.

First: I don't like that there are two 4" ports.

I use the bandsaw a lot, and I have to move each machine in my shop when I use them.

I usually dedicate a 4" hose to the machines I use a lot, but I didn't have a free one for the second port.

I expanded my 4" dust plenum and make more valves.

The Jet DC-1100 has suffucient CFM and the 4" dust plenum has suffucient cross sectional area to support two 4" valves open at the same time or one 6" valve.

I made a 6" valve, with a 6" hose, a 6" to dual 4" port 'Y' so there is only one valve I have to open for the bandsaw.

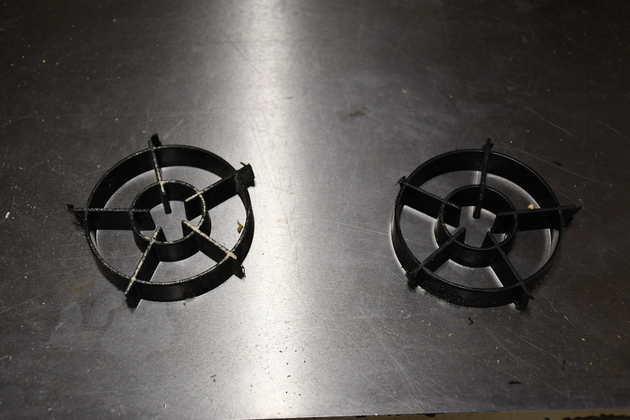

Second: the ports have a kind of grill cast into the plastic.

When I saw, with the grain, the blade produces stringy fragments which quickly clog the port.

I removed the plastic grill in the port.

The first problem I encountered, dust collection:

Number 1:

The 14SFX requires two 4" ports and its a nuisance moving the sander's 4" hose to the second port then having to open two valves on the ceiling plenum.

so I did a little thinking and decided to make a 6" valve and replace the original 4" bandsaw valve.

Done and works great.

Number 2:

The grill in the ports gets clogged when you make certain cuts with the 2/3-VPS blade which I am rapidly falling in love with.

I am going to remove the grill to get rid of this problem.

Number 3:

I have had Delta and two Jet bandsaws, none of the dust collection worked well, there isn't a vent to let air into the lower wheel area so there is no real air flow.

I have found that tools with 4" dust collection (like my router table) stay cleaner (no dust buildup) if you have an air vent into the area where you have a dust port especially when you are using 4" dust ports.

Both dust ports are in the lower wheel area, so by allowing air into the lower wheel area you create a "sweeping" action that helps keep the area cleaner.

I keep the lower wheel door adjar when using them, consequently there is a whole lot less dust buildup in the lower wheel area, the lower blade guides, and none on the floor.

Jet could jump ahead of the competition by adopting a radial damper in the lower front door.

Another Problem:

After 3 months of use, I noticed the lower blade guide bearings had seized!

All the other bandsaws I've owned had ball bearing blade guides, and none of them ever seized, so this is kind of a mystery.

I soaked them in WD-40 and could finally turn them but it was hard and had a rough feeling?

I called Jet (12/28/18) and they sent me a form, which I filled out immediately and sent back.

We'll see what happens.

I had a problem with the saw's fence, when I unpacked it, there was a lot of aluminum corrosion on it which wouldn't allow it to be exactly vertical. So I went back to the Kreg fence.

|

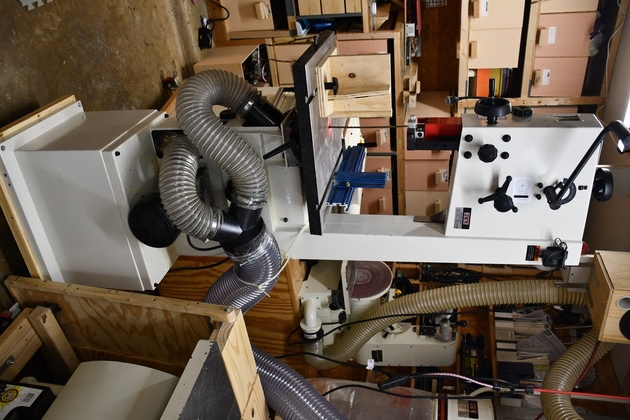

New Jet-14SFX bandsaw, Sept. 18 2018. Note it has it's own fence, the one I couldn't get vertical to the table. |

|

Jet-14SFX bandsaw. This saw's tension is much easier to adjust than the 14-DXPRO, and the blade roller guides are larger and easier to adjust too. |

|

The 6" dust hose with 'Y' and two 4" hoses. |

|

I removed the grills from the saw. |

|

I have to keep the front door adjar in order for there to be enough air flow for the dust collection to work. |

|

Closer look, I keep the lock turned so the door is adjar, the vacuum will keep it against the knob. |

|

This is the lower front door,

I think Jet should put a "radial damper" with a fan grill in the lower left corner (RED CIRCLE).

The radial damper (AKA Butterfly damper) would allow adjustment of air flow into the lower wheel area and the fan grill would keep fingers etc out of the wheel and blade.

By partially closing the damper more air flow is forced to come through the lower blade guide area while the remainder flows through the lower wheel area, sweeping out dust.

This would probably be appropriate for all bandsaws with dust collection.

|