|

|

|

|

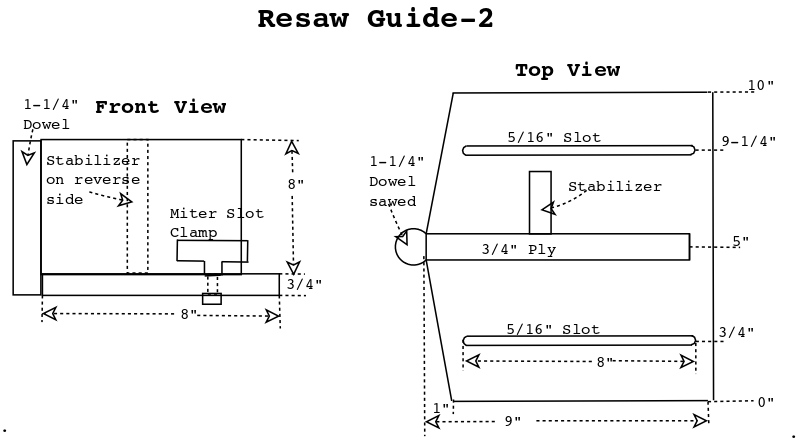

Resaw Guide 2

| ||

|

|

|

|

Resaw Guide 2

| ||

| Rsw#2Construction | Diagram | Saw Jig |

After using feather boards for resawing for some time I decided its time to make a better back side guide for resawing.

I used 3/4" plywood, a 1-1/4" dowel, and two miter bar clamps.

The dowel needed a flat side parallel to the opposite side.

I decided to use my tablesaw to saw a flat on a round dowel, so I had to make a special jig to hold the dowel.

I didn't take a lot of pics on this project, I did it in one afternoon then allowed the glue to totally set overnight.

|

The 1-1/4" dowel. |

|

Dowel sawing jig. Its a 2x3 with a round groove machined into it's center down one edge. The groove was cut using my router table and a 5/8" round nosed bit, centered in the edge of the jig. |

|

Here is how I used it, the 2x push block on the left, you can see the saw blade in the background. |

|

After sawing. |

|

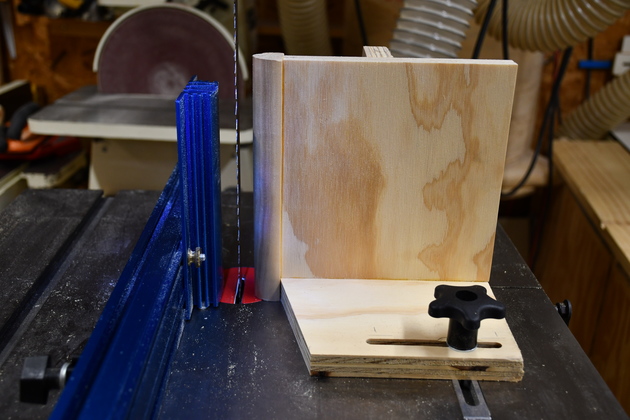

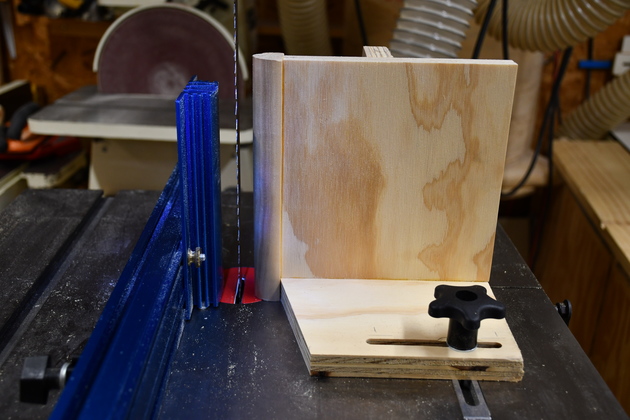

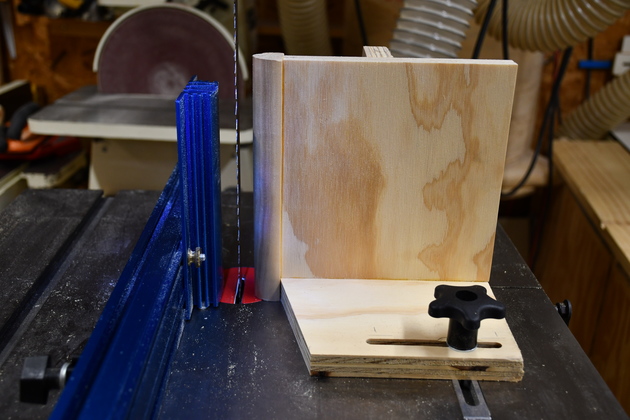

Gluing the frame together. Make sure all the pieces are square cut (check the table saw's fence before sawing). |

|

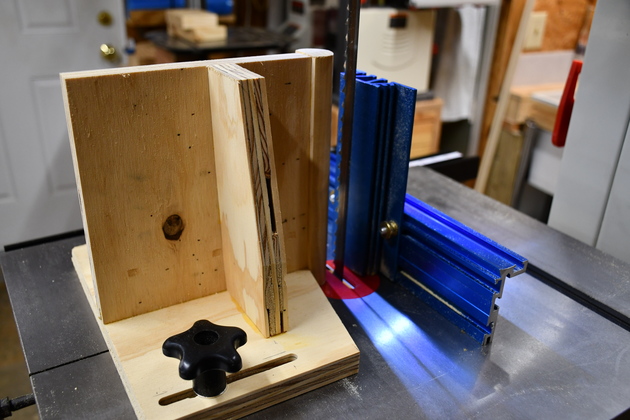

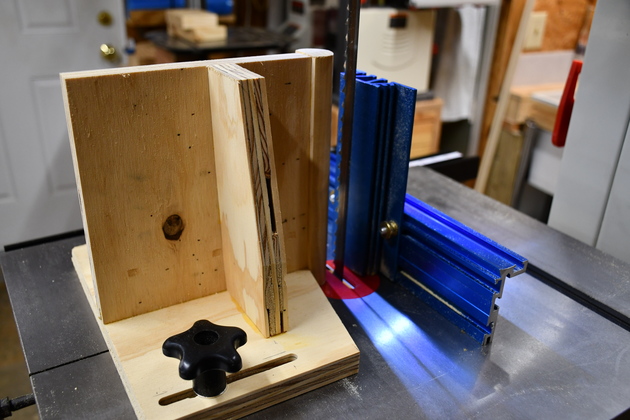

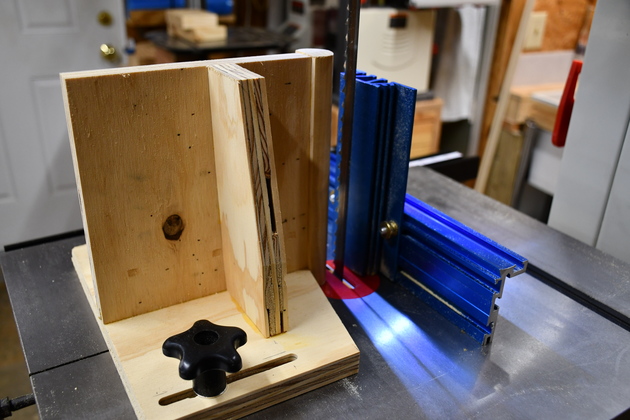

Closer look. Thats the stabilizer pointing to the left. |

|

Gluing on the dowel. The stabilizer is pointing into the camera. |

|

Painting the guide. |

|

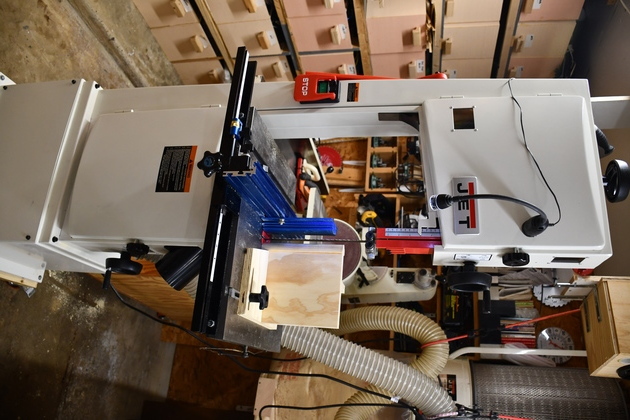

The resaw back guide on the bandsaw. |

|

Closer look at the front. |

|

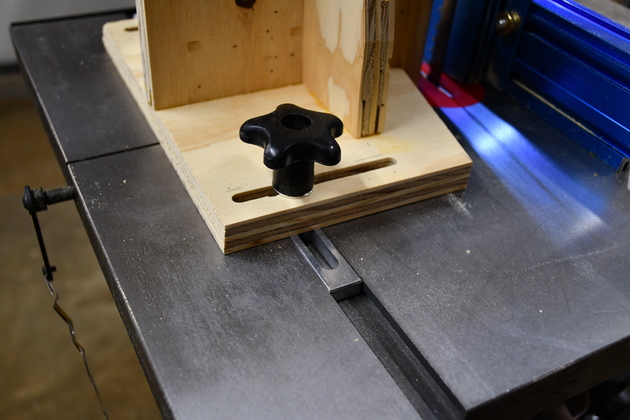

This is the back side, you can see the stiffener. |

|

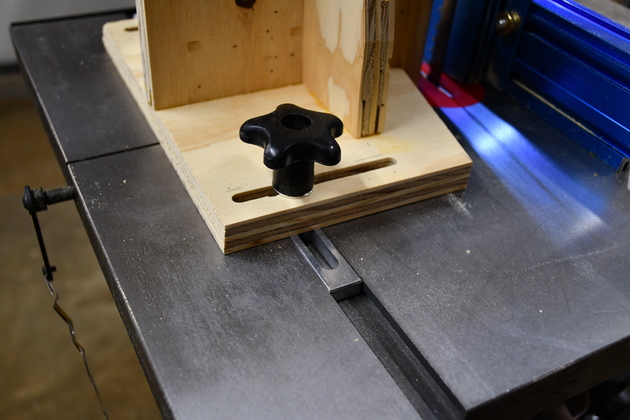

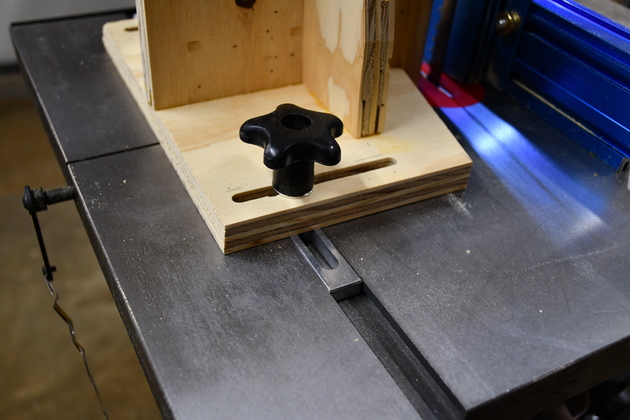

Closer look at the miter clamps, from Rockler. |