|

|

|

|

|

|

I like natural wood especially pine, with knots, for furniture. For most of the furniture I make I use SYP (Southern Yellow Pine). It's difficult to find large panels except pine (not southern yellow) plywood for cabinet sides and drawer fronts (doesn't take paint & stain same as SYP). In the past I resawed pine (to about 5/16" thick) and edge joined them to get a wide panel.

SYP (Southern Yellow Pine) is the strongest pine, but has the problem that it tends to warp and crack with age. So I have been making laminated panels for cabinet sides and drawer fronts. I saw thin (usually 1/8") pine slabs from a 2x8, edge join several untill I have a suffuciently wide panel then laminate it to a thin plywood backing (3/16"). As I resaw thin panels from the side of a 2x8 SYP, I plane the 2x8 remnant before resawing again. This keeps it from cracking (so far) and looks nice.

|

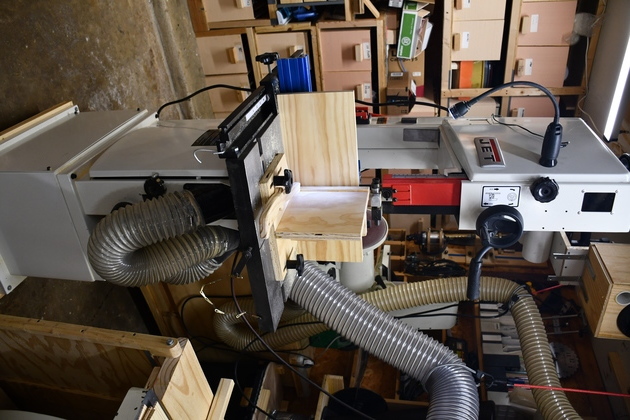

Bandsaw resawing. |

|

Closer look at 2x8 being resawn. |

|

Resawing the last two 3/16" slabs from a 2x8. Note the two resaw guides, the blue one on the left is a Kreg, the right one is homemade. |

|

Planing off the bandsaw marks on the planer sled. |

|

Stack of 1/8" thick pine slabs, after passing through the jointer, for inset panel faces. |

|

Glue bead on edge of 1/8" thick panel slab for edge joining. |

|

Edge joining a pine face. It doesn't take much pressure to edge join 1/8" thick panels. The bricks help prevent the panel from buckling under the pressure. |

|

Sanding the edge joined pine face before laminating. |

|

Plywood (3/16") ready to laminate the face to it. You can just see the face in the lower left corner. |

|

Note the Rockler Quick Disconnect 5 point star knobs and the 'bondo' glue spreadder from Walmart. |

|

Close up of the 'bondo' spreadder. |

|

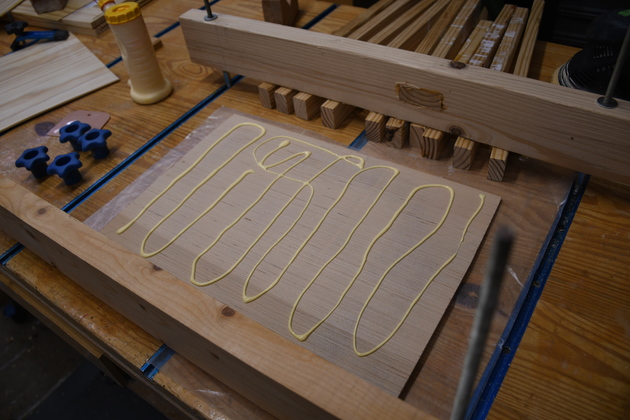

Bead of glue (Titebond II) on the backing. |

|

After using the 'bondo' glue spreadder. |

|

Sure enough one did wiggle and you can see the wedge. It doesn't wiggle any more. |

|

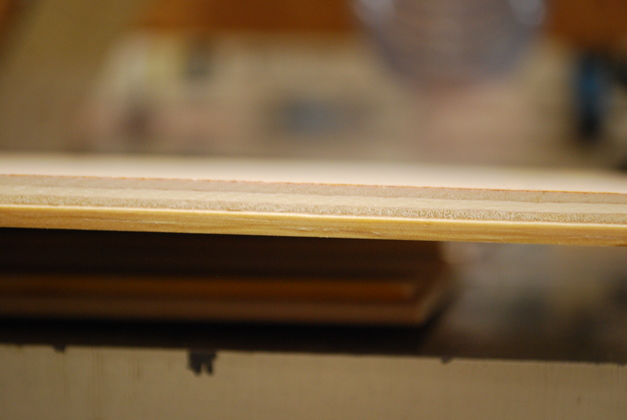

Edge of a laminated panel insert. This should be 5/16" thick. You can see the plywood on top and the pine face below. |

|

Large laminated panel, you can see the slight overlap of the face to the back panel. The overlap will be sawn off for final fit into the frame. |

|

Two panels being glued into a footboard for one of our storage beds. |

|

A foot board with laminated inset panels glued in and ready to paint. |

|

|