|

|

|

|

|

|

Resawing is sawing a board edgewise, to that I get a thinner panel the same width as the original board. I resaw boards to get drawer sides, backs, fronts, shelves, and inset panel faces.

I want inset panels with pine faces that match the SYP (Southern Yellow Pine) frame material. A problem with SYP is it likes to warp, crack, and twist. To prevent this, I laminate a thin pine face (1/8" thick) to a plywood backing (3/16 thick plywood). To make these inset panels I resaw then plane SYP into 1/8" thick slabs then laminate them to a 3/16" plywood backing and finally. The laminated panel is 5/16" thick, note the inset panel rabbet. These laminatd panels are slightly oversize, so after laminating, I trim them to the exact size for the inset and glue them in.

|

Resaw operation on the bandsaw. Resawing is sawing edgewise to make thinner slabs of wood. |

|

A little closer look at a 2x8 being resawn into slabs for laminating. |

|

Resawing 3/16" SYP slabs from a 2x8. The 2x8 is already cut to length. These will be planed down to 1/8" thick. |

|

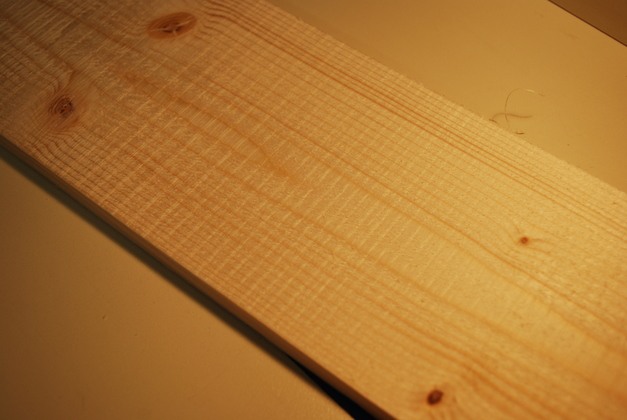

Resawn pine slab. After resawing the sawed faces are rough so I pass them through a jointer. |

|

Planing after resaw. This is a center core being planed before resawing off another face. This planer will plane a 1/8" thick face just fine. |

|

Pine panel faces ready to laminate. |

|

I route out a rabbet on the back of the frame for the inset panels. |

|

Closer look at inset rabbet. This rabbet is 1/4" wide and 5/16" deep to accomodate the laminated panel. I will chesel out the corners so they are square. |