| |

|

|

|

|

Chest Of Drawers

|

10/02/16: Page Origin

Click For Larger Pic

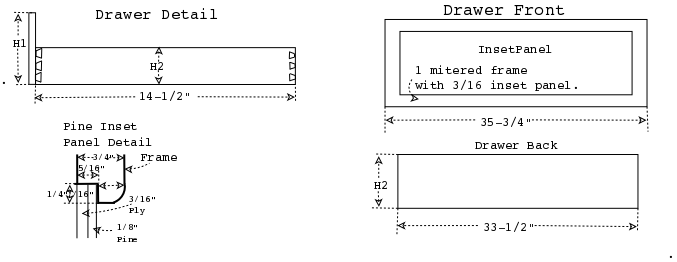

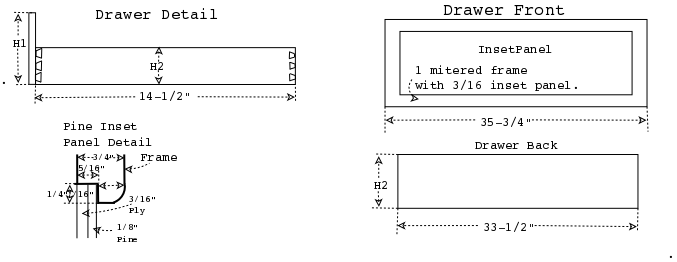

Drawer Sizing Info:

Drawers are 33-1/2" wide.

Top drawer: H1 =4-1/2", H2 = 3-1/2"

Lower drawers: H1 = 7" and H2 = 5-1/2"

All inset panels have a 1/4" wide rabbet on all 4 sides.

Making the panel 1/2" wider and higher than the opening.

Drawer Frames

|

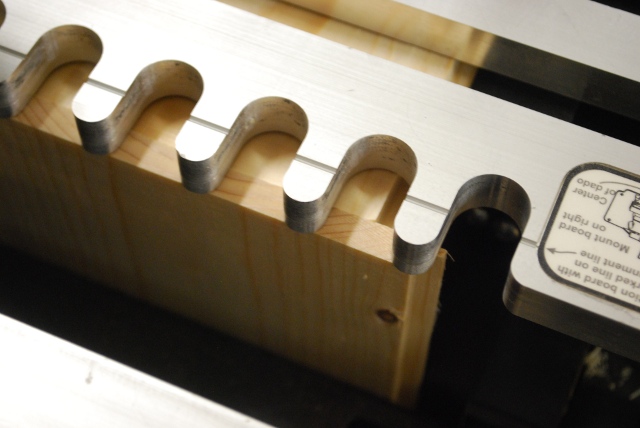

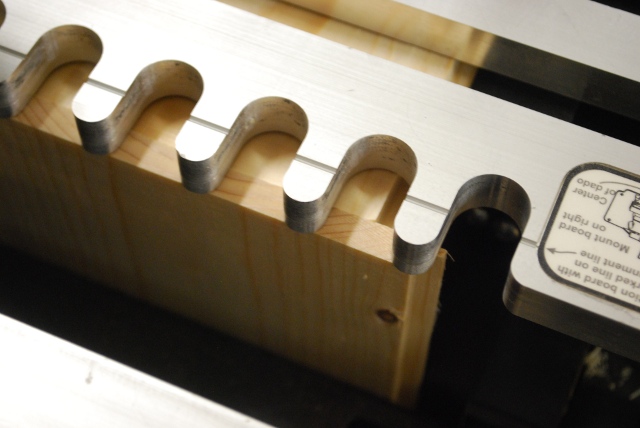

You can see the bottom rabbets cut into the lower inside edge of each side and back.

|

|

Dovetail jig setup on the woodworking bench.

|

|

Close look at a front and side set up in the dovetail jig, ready to cut.

|

|

Front/back pieces sticking out from the top of the jig.

Side pieces always in the front of the jig.

You can barely see the bottom rabbets.

I always use the bottom rabbets for orientation in the dovetail jig.

Better look at detail of bottom rabbet.

|

|

Drawer sets dovetailed.

Two sets, front/back on the bottom, sides on top.

|

|

Top drawer frame in glue clamps.

The Rockler "ClampIts" hold the frame square while the glue sets.

|

|

One of the "ClampIts" clamped in the corner, making sure the frame is square.

|

|

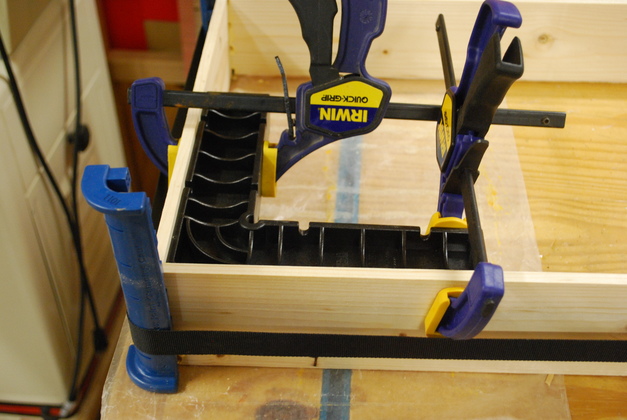

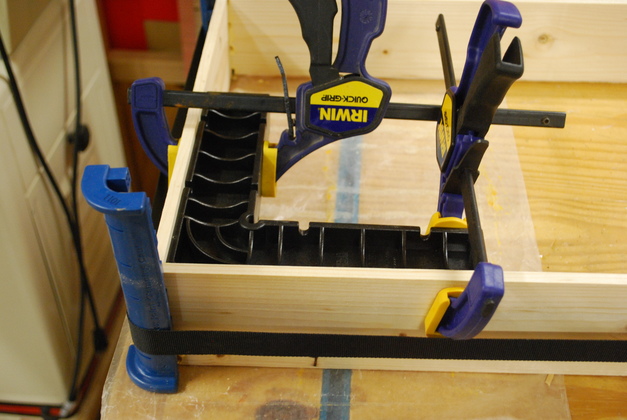

One of the lower drawers in the clamps.

I say clamps, I'm actually using a clamp strap, with Rockler cawls on the corners.

|

|

Line of 7 drawer frames, glued, ready to sand and glue in bottoms.

| |

Build 2.

|

|

|

Drawer bottoms cut out.

|

|

Drawer bottom being glued in, note the hammer, pliers, and wire nail drawer, I use wire nails to hold the bottom in place while the glue sets.

|

|

Drawers being painted.

|

|

Drawer frames mounted in cabinet.

|

|

Note the inset panels in the side of the cabinet.

|

|

Drawers, on slides, mounted in the frame.

No fronts yet.

All the drawers are identical, the difference is the fronts.

|

|

Drawer extended.

|

Drawer Fronts

The drawer fronts will be made with resawn pine fronts and plywood backs, laminated together for form an inset panel in a 1" x 3/4" pine frame.

|

Lumber sawed to length for drawer fronts.

|

|

Pine marked for resawing at 1/8" thick panels.

|

|

Pine facing sawed for the top drawer.

|

|

Two outer resaw cuts marked on a 1x6 for pine facings.

|

|

Pine facings for 3 lower dawers resawed to 1/8" next to an unresawed 1x6.

|

|

Plywood backs cut out on the left, pine resawed panels on the right.

|

|

Glue applied to top of plywood backing.

|

|

Glue spread on a plywood backing.

|

|

Pine panel, under pressure, being laminated to it's plywood backing.

|

|

I have begun using clamps to keep the panel and backing aligned while I apply the pressure.

|

|

Clamp in the center, keeping panel and backing aligned.

|

|

Stack of laminated inset panels (plywood with pine face).

|

|

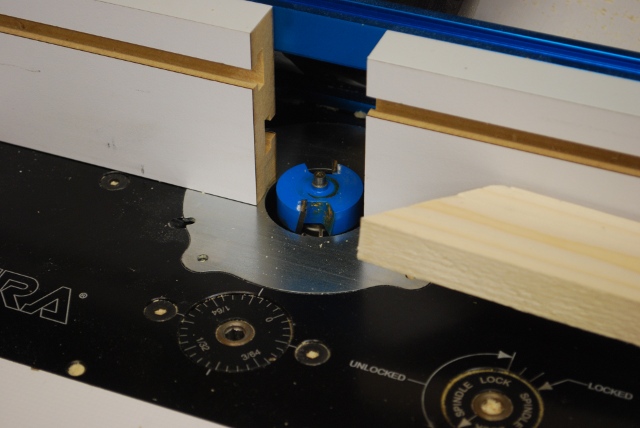

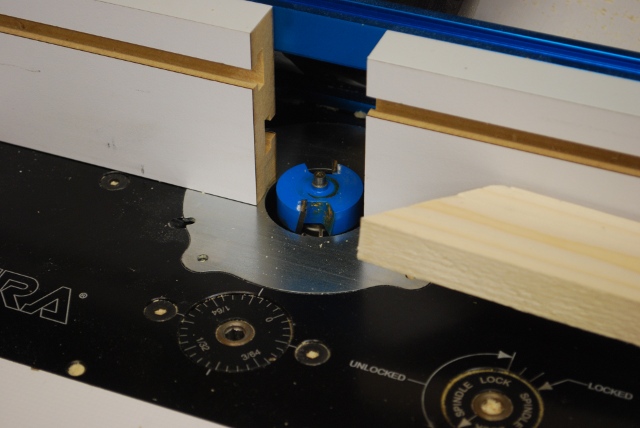

Setup for cutting rabbets in the frame for inset panels.

I use my miter sled on the table saw to cut these 45° mitered ends, for a large number of cuts, its faster than using the miter saw.

|

|

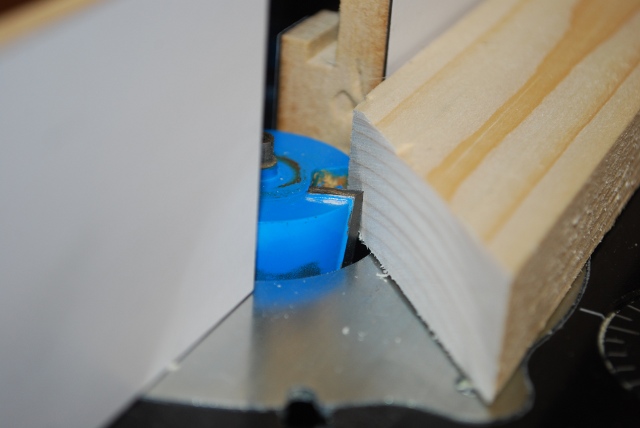

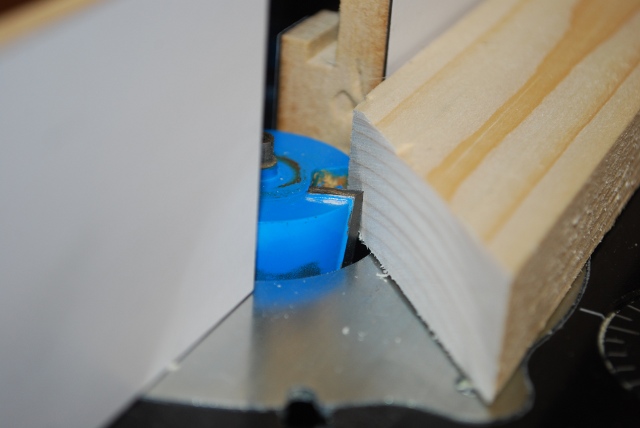

Setup for cutting rabbets, you can see just how much the bit will take.

|

|

Drawer front frame pieces cut to length, ripped to 1" wide, then rabbeted.

I'll be using my miter sled to cut the miters on these.

|

|

Corners rounded.

The two small pieces are the side of the top drawer's front.

|

|

Corner miter with panel rabbet and corner rounding.

|

|

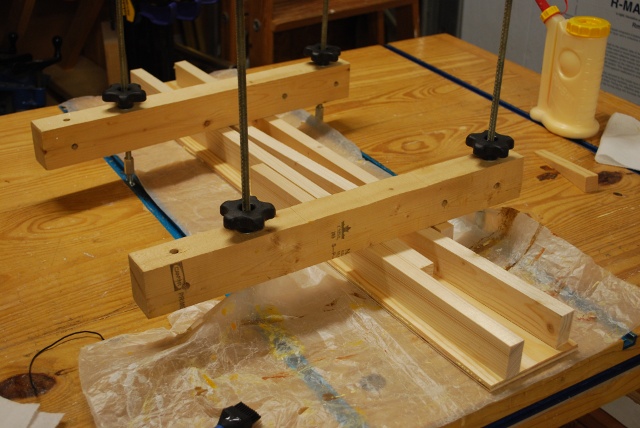

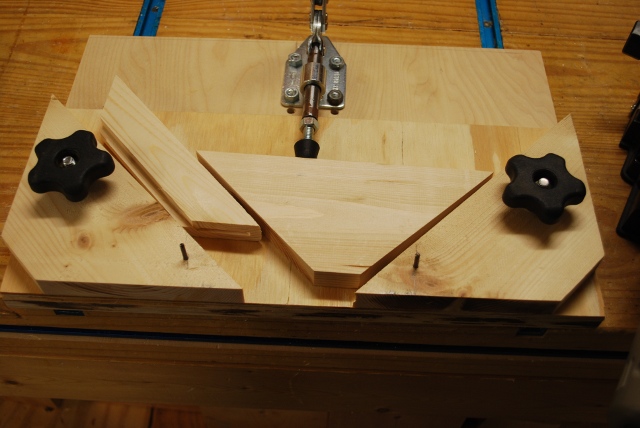

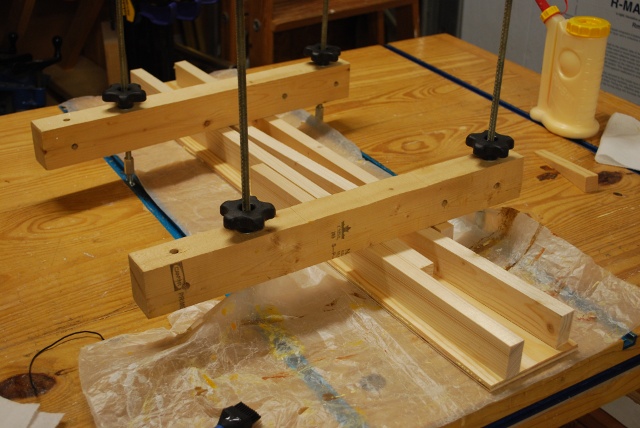

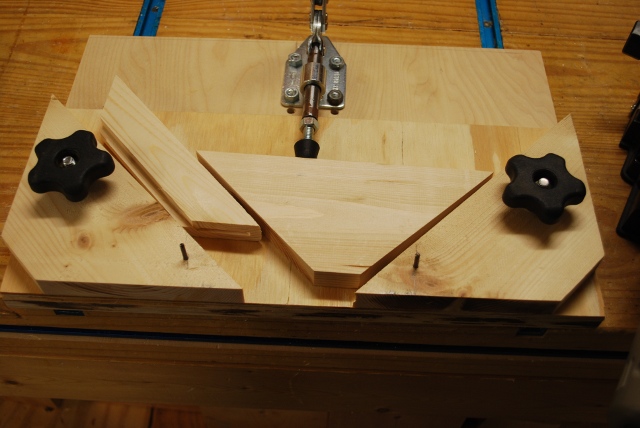

Here is my Miter Slot Clamp Jig.

I make a lot of mitered frames out of 1x2 (and smaller) with type FF biscuits, so I built this jig to cut the biscuit slots in the mitered ends.

It allows me to accurately cut biscuit slots in the end of 45° mitered pieces without measuring and marking every time.

|

|

Gluing a drawer front frame.

|

|

Stack of all drawer front frames, glued, ready to sand.

Note the stack of inset panels on the left.

|

|

Top drawer and lower drawer with inset panel glued in ready to sand and paint.

|

|

Drawer fronts being painted.

|

|

Drawer handles (pulls) being painted.

Link to my Drawer Handle Page.

Notice the two screws, I drilled the mounting holes the run the screws in, just a little, makes them easier to handle while sanding and painting.

|