|

|

|

|

|

|

| Chest Of Drawers Main | Frame | Laminating Panels | Frame Assembly |

| Tall Tee Clamp |

| Miter saw set up for sizing frame pieces. |

| One of the side frames test fit and mark for biscuit slots. |

| First tenon shoulder cut on frame cross pieces using the router table. |

| Tenon marked for end shoulder cut using bandsaw. |

| First end bandsaw cut on lower front frame piece. |

| Tenons cut on 6 frame side horizontal cross pieces, just a little trimming and sanding and they'll be ready. |

| Tenons cut on frame cross pieces, and need a little trimming. |

| Mortise holes marked in frame side verticals. |

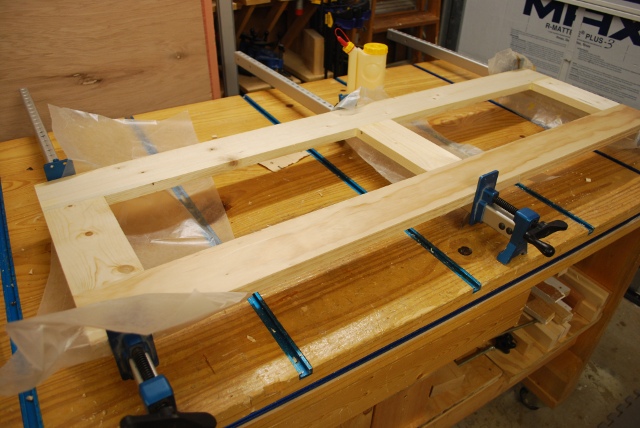

| Frame side piece in glue clamps. |

| Frame side glue set, ready to sand. |

| Sanding glued frame side. |

| Top in glue clamps. |

| The biscuit slots cut into the underside of the top. |

| And the matching slots in the top of the side piece. |

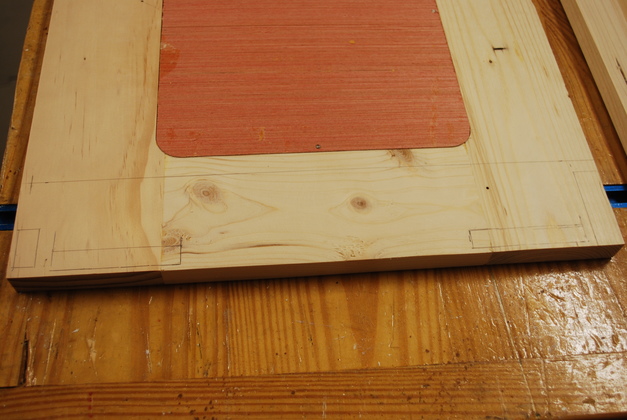

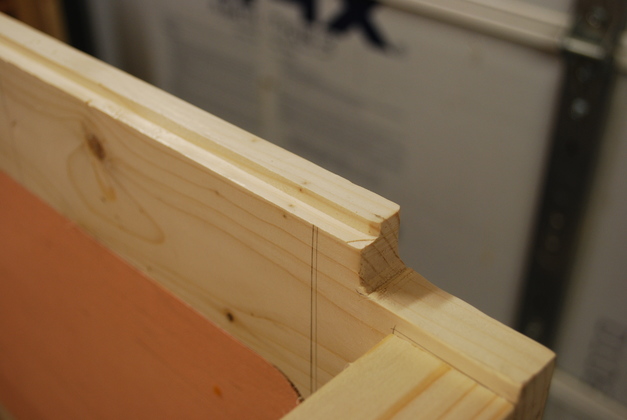

| After the frame side is glued, I rounded the outside corners of the inset panel area. |

| And rabbeted the inside for the inset panel. |

| Pic of the inset panel rabbeting in process. |

| Heres what the workbench looks like while I'm rabbeting, a lot of wood chips. Notice I had to raise the side frame piece up off the workbench to clear the rabbet bit's bearing. |

| Inset panels glued in, and mortises marked. |

| Closer look at lower front mortise marks, you can also see the lower drawer slide center line, 2-5/8" from the bottom of the frame. |

| Mortise after drilling and before cleaning out with a chisel. |

| Mortise being cleaned out after drilling. |

| Lower front mortise after clean out (1" wide X 1/2" high). |

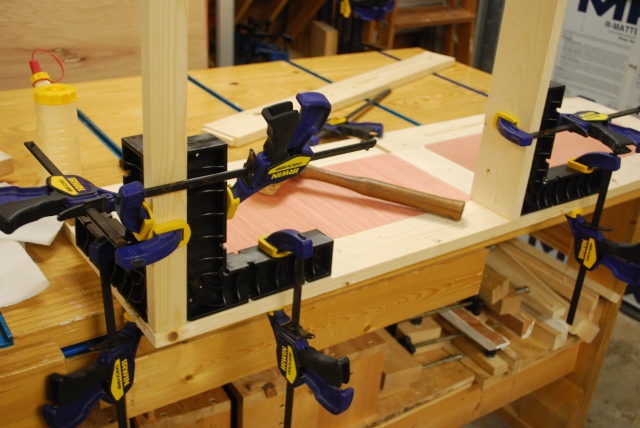

| Gluing horizontal cross brace's tenons into their mortises on the right cabinet frame. Notice all the ClampIt holding everything square. |

| Adding the lower front horizontal cross brace. Again note the squares. |

| Rear horizontal coss supports gluing in place. |

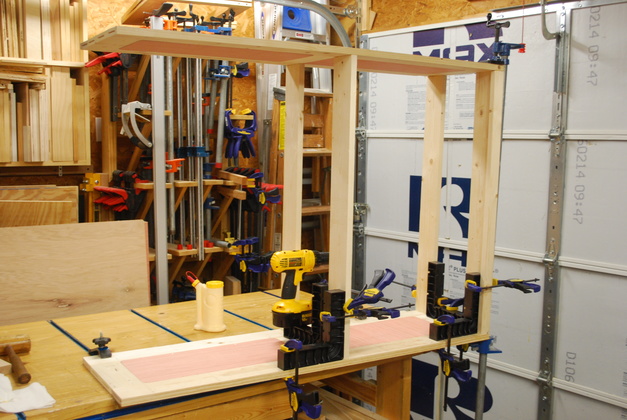

| All 5 horizontal supports gluing. |

| Looking from top of cabinet. You can see the biscuit slots for the top in the top ends of the cabinet sides. |

| Gluing on the top. I made these special tall tee track hold-downs to keep the frame flat on the workbench. Simple but they work. |

| Just an ell bracket with a 5/16" hole, and a 5/16" nut with the threads drilled out, welded to the bracket, a 5/16" threadded rod, with a coupler and short tee bolt at the bottom. |

| Inset panels glued in, upper back panel glued in. |

| Cutout for the baseboard. |

| Upper and lower back panels fit into rabbets. You can see the wire nails I use to hold them in while the glue sets. |

| Front view of assembled cabinet. |

| After rounding the corners, panels glued in slides mounted. Note the panel's grain running horizontaly, the drawer front grain will also be horizontal. |

| Build 2 cabinet complete. |

| Notice the inset panels in the build 2 cabinet. |

| Installed, not the inset panels and how close to the wall it is sitting. |

| Installed in the master bed room. |