|

|

|

|

| Lathe Bench | |||

|

|

|

|

| Lathe Bench | |||

| Back to Lathe Page | Delta Ironbed | Jet 1440 | Power Matic |

I started out with a Jet Mini Lathe but soon realized that I wanted something larger with a headstock that rotated (outboard turning) so I could more easily turn bowls etc. so I bought the Delta 14". The Jet was small enough I could just pick it up and put it on an existant workbench when I needed it, but the Delta was a different matter altogether. The Delta's bed was about 5' long and it weighed over 230lbs. so I needed a good sized, sturdy bench to support it. I had also accumulated several chucks, faceplates, measuring tools, and an assortment of gouges (another 50 or 60lbs.) all of which need a place to stay. An additional problem was with dust control, especially when the headstock was rotated out. In some of my research, I noticed pics of woodturners with older lathes that had a narrow space under the lathe bed to place gouges being used on the current job. As a solution to all these issues I came up with the bench pictured here.

The bench is 48" wide, 18" deep and 34 1/2" high, with 2" risers for the lathe, which makes the lathe bed 41" high. All construction uses loose tenon (#20 biscuits), top is laminated 2x6 pine. The lathe is raised on 2" blocks at either end to provide a handy area on the table top, under the lathe to set gouges while working. Since lathe an bench weigh well over 300 LBS. I used the really good 3" double lock casters from Woodcraft. This is the first tool bench I built and subsequently is a little different from my other benches. The bench has 4 tee tracks, two on front to allow moving the vacuum pickup, and two on the top rear for the dust hood and the arm lamp. The bench had 4 double locking casters rated at 300Lbs ea., when you lock two of them, with a 250Lb lathe on board, the lathe does not move.

NOTE:

I replaced the lathe in 2014, some of the pics here show the new Jet lathe, the rest show the old Delta.

|

Close up of vacuum support pivoted out. Notice the adjustment knob for horizontal positioning along the bench front, pivot adjustment, vertical position of suction, and angle of suction. |

|

The vacuum support folded against the bench. |

|

With the headstock rotated. Note I'm turning a piece of PVC to fit a blast gate. You can also see the dust hood behind the bed, it is mounted on a tee track so it can be moved anywhere along the bed. |

|

This is where I use the lathe, note the DC power remote in the red circle at the top center of the pic. |

|

Dust support moved to the side to allow drawers to open. |

|

The top drawer open showing tools. |

|

Middle drawer open showing chucks and faceplates. |

|

The gouge storage space under the bed. Notice the drawers don't have pulls, they just have finger holes, pulls would obstruct the traversal of the front dust support. |

|

Top gouge drawer open. |

|

Second gouge drawer open. |

|

Another gouge drawer. |

|

Back of the lathe bench. |

|

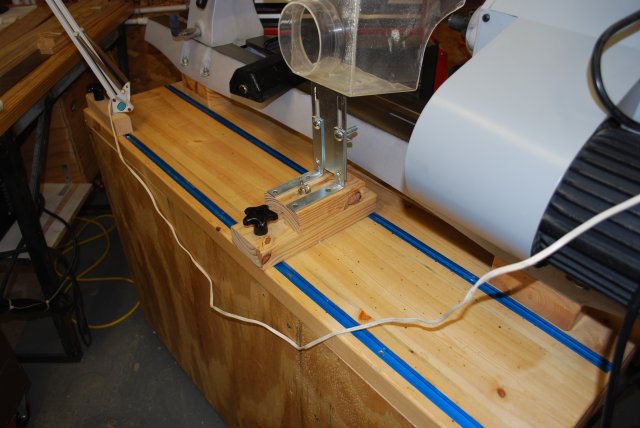

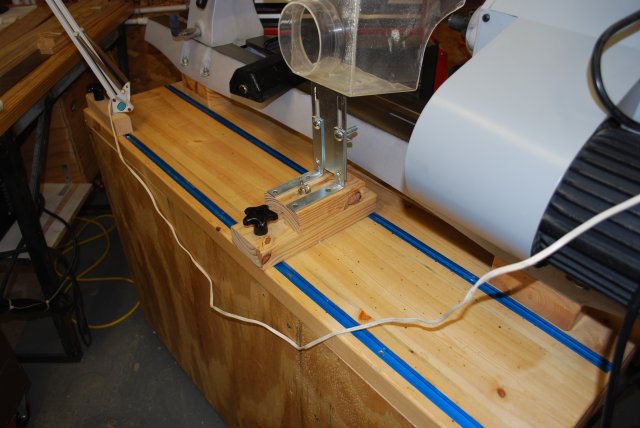

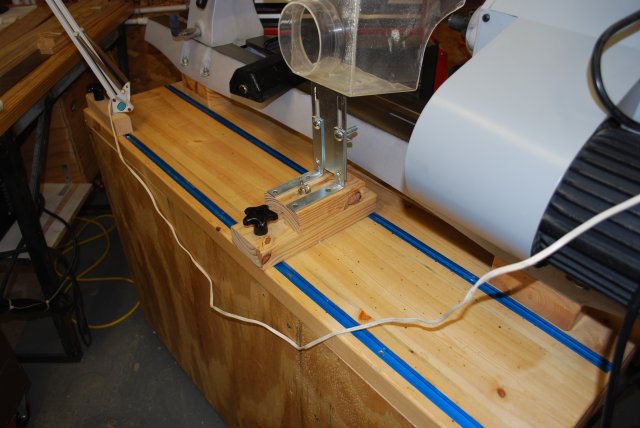

Tee tracks on top rear, note dust hood mount and arm lamp mount. |

|

New chip collector on the lathe bench as of 05/30/15. |

|

Closer pic of arm lamp supp, note extra dowel in close end to keep it alligned in tee track. |

|

Lathe stored, note how every thing fits together. |

|

Note how the lathe bed overlaps the mortiser bench. |

|

The back fits between the back of the welding bench and the tool box. |

|

From the welding bench. |