|

|

|

|

|

|

|

|

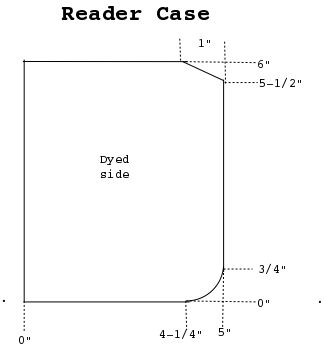

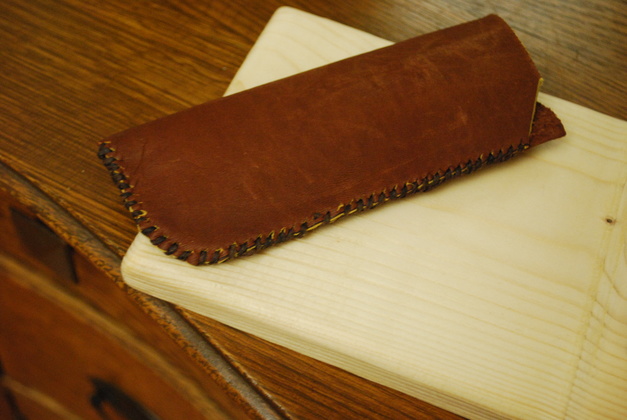

We frequently have problems finding good cases for protecting our reading glasses (readers). So I decided to make some simple cases from leather.

| A pair of duck billed vice grips usually used for welding sheet metal. I made a pair of these once by welding two flat metal strips to a regular pair of vice grips, or get some at Harbor Freight as Welding And Sheet Metal Clamps. |

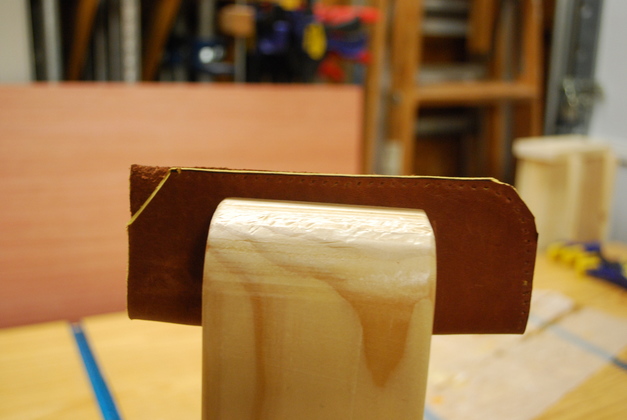

| Fold the leather and match the sides up for the case and clamp in the duck bills to hold it secure while punching thread holes. |

| I used a 3 prong to go around the corner. Again put the first prong in the last hole of the previous punch set. |

| Now move it to the stitch horse and clamp it in. |

| I'm not great at stitching, but I'm learning. Note the "around the edge" type of stitch. |

| I use a sewing awl on the stitch horse. The next time I make one, I'll get some pics of the actual sewing. There are a few sewing pics on the Stich Horse Page. |

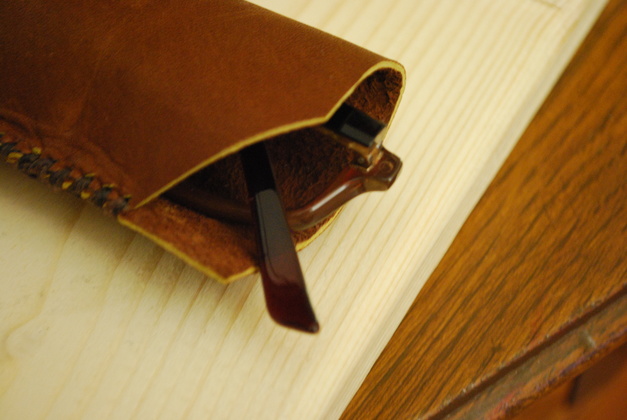

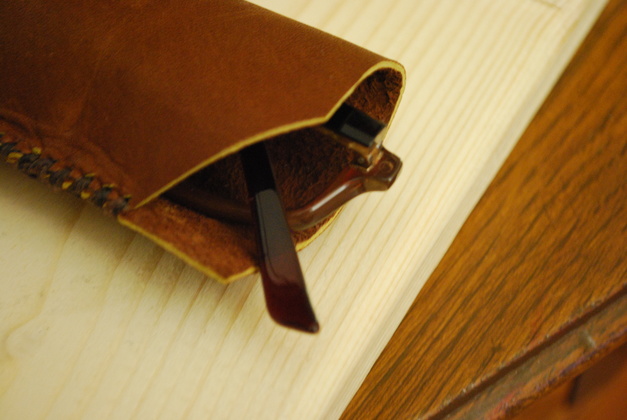

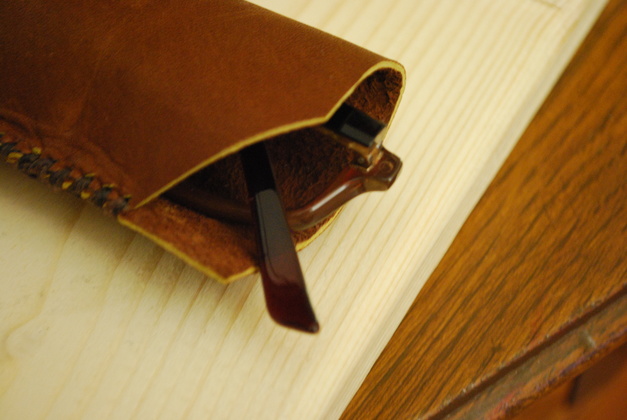

| With a pair of readers. You would have to make the case wider for larger glasses. |

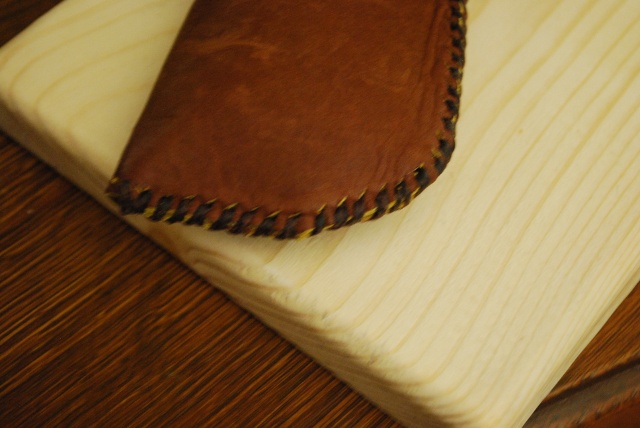

| Lower end. Again, you can see the "around the edge" type of stitching. |

| Top, the cut off corner seems to make it easier to put the glasses into the case. |

| A couple of cases, the left is one I've carried for over a year, the right is brand new. Notice I used different stitching techniques. |

| Side view. |

| With glasses in both. |

| Close up of straight stitch top side. |

| Close up of straight stitch bottom side. |