Square Board Joints

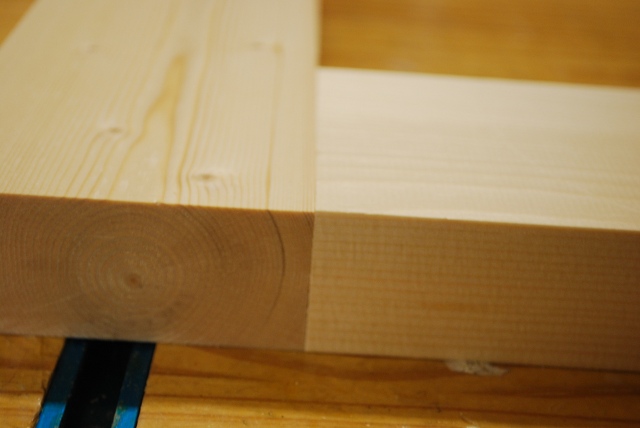

A 2x4, when it comes from the mill (lumber yard) is 3-1/2" wide and 1-1/2" thick and has slightly rounded corners (this is true about all 2x framing material). For some projects I mill about 1/16" off each board face so the 2x has nice flat face and square corners so the joints will be flush. The resultant 2x4s will be 3-3/8" by 1-3/8". In the following pics I talk about milled and unmilled lumber, I am speaking of milled lumber that I have run across my jointer to remove the rounded corners.

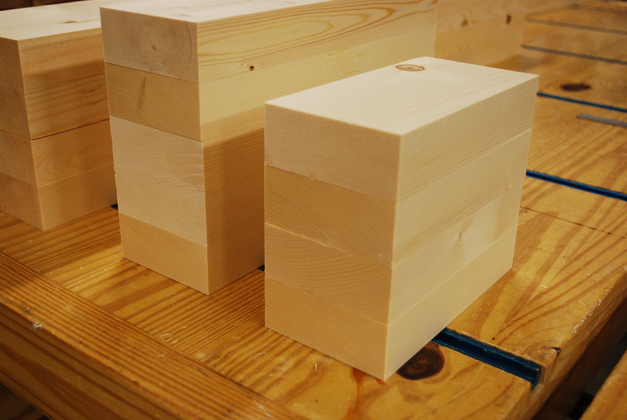

| Here are frame pieces after cutting to length and before milling. See the rounded corners of the 2x4s and how they leave a noticable crevice between boards. |

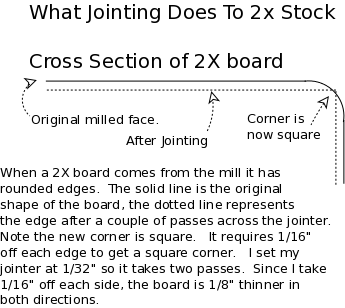

| After jointing, the cracks between boards are very hard to see and corner edges are nice and straight. Even makes the faces flatter, and smoother, and removes much of the dings and gouges the lumber had in getting to, and at, the lumber yard. The 2x6s on the left will be a table top. |

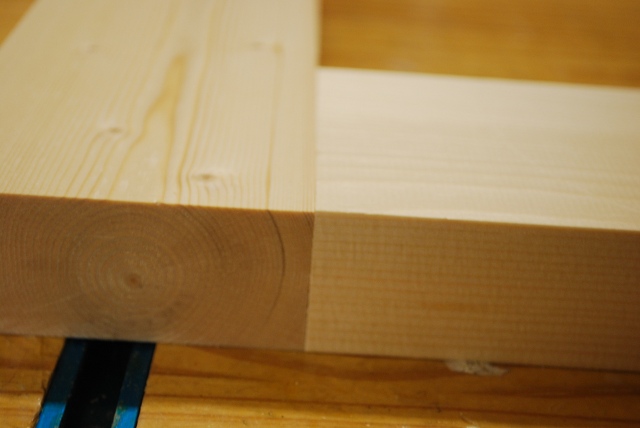

| Front quarter view, again showing how the cracks are now hard to see. When properly joined, they will be hard to feel and only visible by the difference in grain. |

| Side by side comparison of unmachined and machined boards. |

| Unmilled joint. |

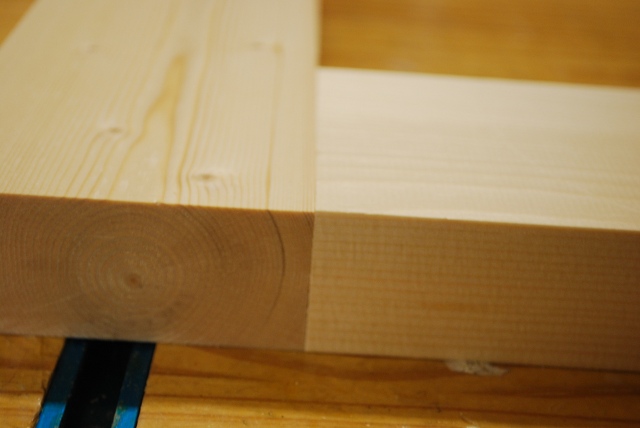

| Joint using milled lumber. |

| Unmilled joint from above. |

| Milled joint from above. Makes a huge difference in the appearance. Note the nice straight, sharp corner running across the joint. Makes the project look a whole lot more professional. |