|

|

|

|

Lumber Prep

| ||

|

|

|

|

Lumber Prep

| ||

| Sizing | Ripping | Resawing | Planing |

| Resawing Page |

I make most of my things from 2x8x8' SYP. I do this by cutting 2x8s to the lengths I'll need, then ripping to the correct width, then resawing to the correct thickness (if necessary). I also plane the bandsaw marks from resawn lumber and to guarantee all pieces are the same thickness.

|

All frame lumber (2x8s) on the work bench (except the 3/4" plywood). |

|

Cutting 2x8s down to length. |

|

Frame pieces cut to length. |

|

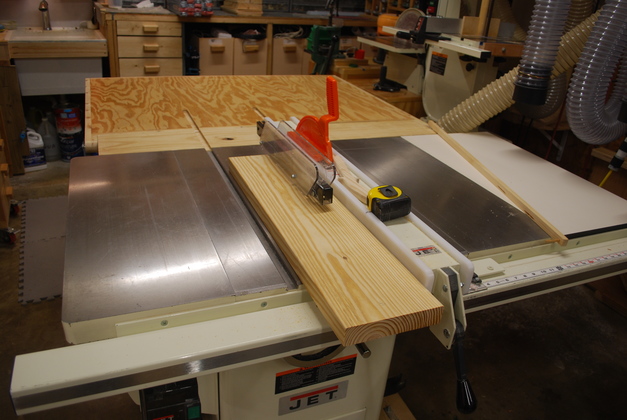

My sizing operation. The workbench is the same height as the saw's table. |

|

Ripping 2x8s into 2x3s and 2x2s. Note the outfeed table. |

|

Complete set of all the main box rips, stacked on the table saw's outfeed table, ready to mark and resaw. |

|

Lumber rips done. |

|

Marking 2x to be resawn into 1xs. |

|

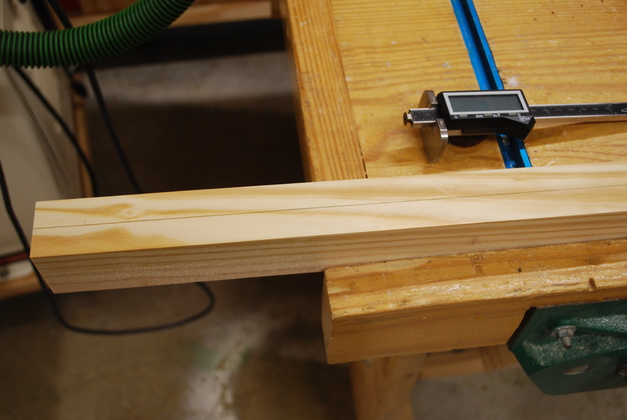

Closer look at resaw mark. |

|

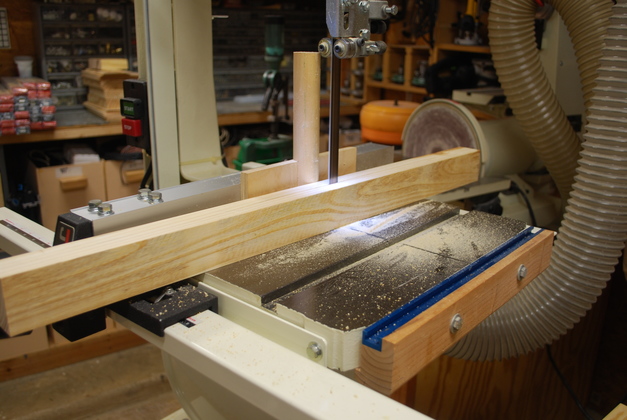

Resawing a 2x into a 1x. Thats a Jet JWBS-14DXPRO saw and a TimberWolf 3/4" 3TPI blade. The resaw guide is one I built. |

|

Closer look at the resawing. Note sawing right down the center the two halves should be equal thickness. |

|

Lumber resawn into 1x2s and 1x3s. |

|

|