|

|

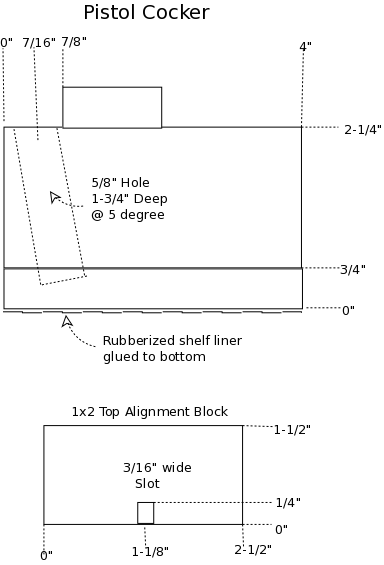

Pistol Cocker

|

11/23/13: Added views of non-skid bottom.

07/29/12: Added dimensions.

Betty was having problems cocking automatic pistols so I came up with this, a wooden pistol cocker.

Its just 3 pieces of wood glued to gether wich a notch for the front sight to guide the pistol and a deep hole to accomodate the barrel.

We've tried it on 9mm, 357Sig, .40, .45, M&Ps, M&P Compacts, XDMs, and even a Glock we owned for a short time.

The block is made of a 4" long piece of 2x4 and 1x4, glued together with a small 1x2 block on top.

I found the barrel hole had to be 1-3/4" deep, 5/8" diameter, and at about a 5° angle.

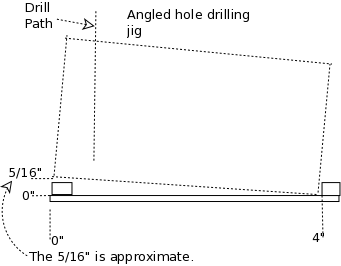

To drill the hole at a 5° angle, I made a little board with a stop block and a riser about 11/32" high to prop up the end being drilled (see pic below).

The sight notch is 3/16" wide and 3/8" high.

We also glued rubber shelf liner to the bottom so it wouldn't slip on or marr a slick surface.

I put a rectangle of the rubbery shelf liner on the bottom to give it a non-skid surface, you don't want this thing slipping while your cocking a pistol.

Here are the pics on the non-skid mat.

|

Prototype from the other side

You can see its made by gluing a 2x4 block on top of a 1x4 block about 4" long.

|

|

Prototype looking straight down into the barrel hole

The barrel hole is at about a 5° angle.

|

|

Prototype cocking an XDm 3.8", it also cocks a full size M&P .45.

|

|

First Production run, we gave a bunch of these away.

|

|

From the front.

|

|

From the side

|

|

Straight down the barrel hole!

|

|

I put the rubbery shelf liner on the bottom to create a non-skid surface and it works great.

To apply it, I cut out the rectangle, put a coat of the poly on the bottom and just put the shelf liner piece directly into the poly while it was wet.

|

|

Close up of the non-skid bottom.

|

|

Here is the same kind of stuff I used, this role if for a different project.

|

|

Here is the bottom of a pistol cocker after several years of use at the range.

|