|

Refurbishing Reloading Equipment

|

From time to time Southwest Ammo takes in some used reloading equipment as a trade in and I get the fun of cleaning it up and refurbishing it. I enjoy this, its a little physical activity and some thinking required. A number of these have been Mec Shotshell Presses, and I have never reloaded a shotshell, so I get to learn something.

| In the past I have refurbished: | ||

| RCBS Rockchucker-II Press. | Lyman 450 sizer/lubricator. | RCBS Partner Press. |

| RCBS Uniflow Powder Measure. | RCBS Trimmer-2. | RCBS 4X4 progressive press. |

| Mec 650 - 12 Ga. shotshell press. | Mec 600 Jr. .410 shotshell press. | Mec 700 12 Ga. shotshell press. |

| RCBS JR-2 | ||

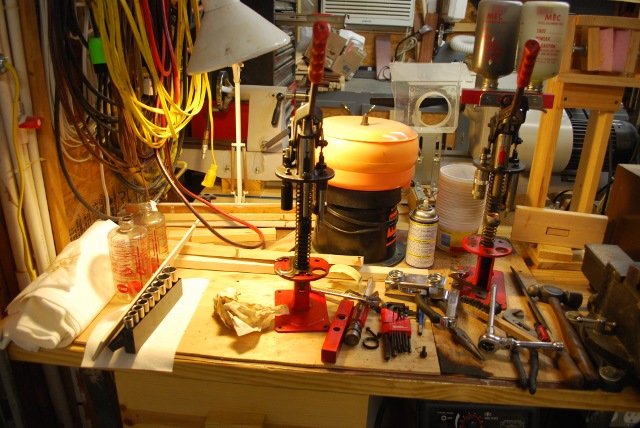

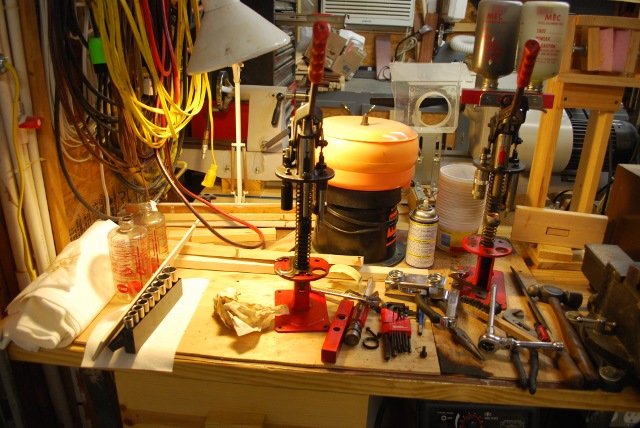

| Two Mec shotshell presses on my metal working bench: a .410 on the left and a 12 Ga. on the right. The .410 is a Mark-5, the 12 Ga. appears to be a Mec 700 Versamec made before 1982. |

|

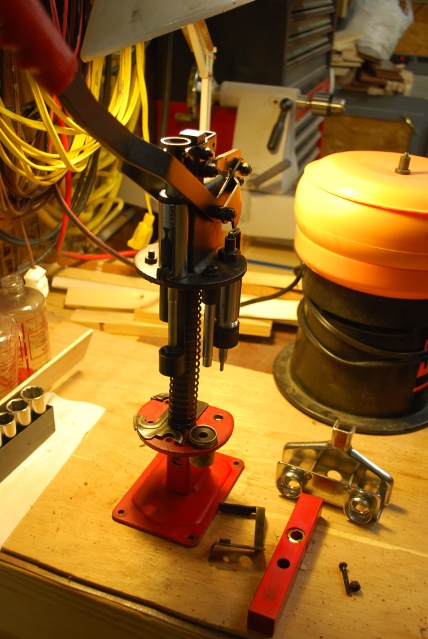

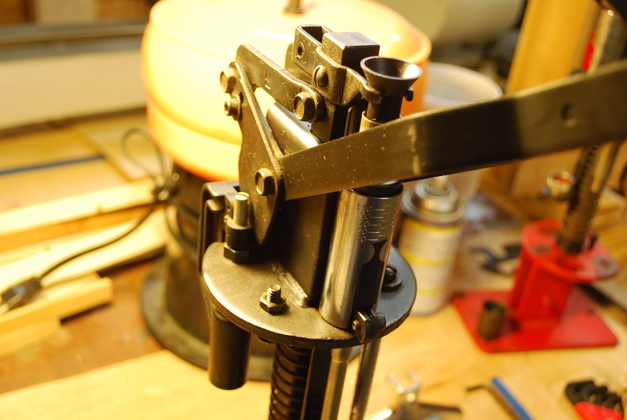

An RCBS Rockchucker II after cleaning still disasembled.

Note: no handle. |

| The RC-IIs rods, pins, ram, snap rings, wave washers, and toggle block. |

| The main frame of the RC-II. |

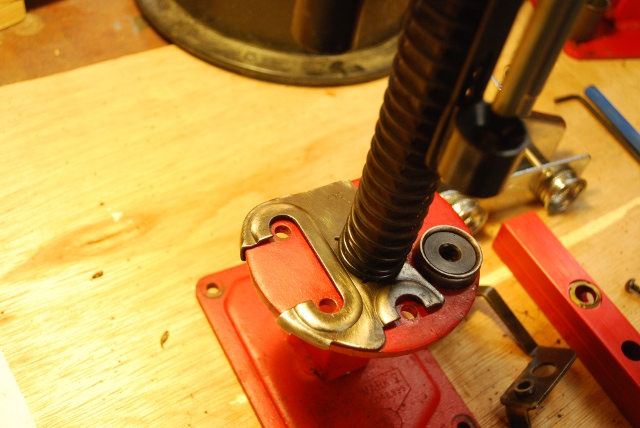

| Closeup #1 of the 12 Ga. This is a pretty good look at their condition when I get them. I have removed the shellplate, and repriming cup. This is a Mec 700 Versamec made before 1982, no wonder its in rough shape. |

| A closer look at the base, the shellplate is laying on top (on the left) and the reprimer cup has been removed (laying on bench in front of base). You'll notice files, wire brush, sand paper, misc tools for disassembling and reassembling the presses on the bench. |

| You can see some of the rust spots on the shiny parts. The polished parts all had rust flecks and had to be brushed, Mec apparently does a decent job of polishing, cause when I brush it the rust comes off leaving a like new finish. At first I thought these were chromed, but now I'm not sure, even after cleaning them up. |

| Another closer look showing more rust and dirt, even bad on the handle. Remember, this press is over 30 years old. |

| Upper end of the 12Ga. |

| This is the base of 600 Jr. Mark V (.410), after cleanup, it still needs a Spindex (the thing that starts the crimp). This Spindex is not a good design, it is made of plastic and pivots on a small knob turned on the end of a 1/4-20 bolt. It just snaps on, and off, not enough resistance, of course this is an old press, it may be just very worn. |

| Most of the parts of the Mec 600Jr. Mark V. |

| I don't usually take the actuator section apart if there is no bad rust, I just flush it with WD-40 and wipe every thing. In this case the chrome was spotted so I removed the charging bar holder (Mec calls it the "Measure Only"). |

| The shell plate cleaned up ok. I always spray these with Boeshield, to protect it from rust. Boeshield was invented by Boeing to protect aircraft parts, I get it at Rockler's, and spray all the machined beds of my wood working machines with it, so far, no rust. |

| An RCBS 4x4 progressive reloader when I got it. |

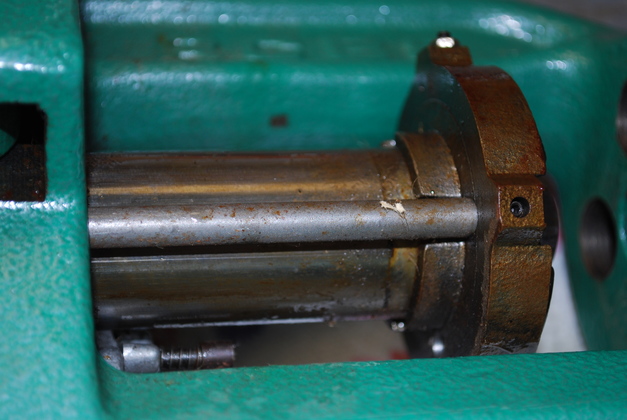

| Note how the ram and primer drop tube have a lot of rust spots. |

| Rust on the handle. |

| Another shot of the 4x4 ram. Believe it or not, this all cleaned up shiny and bright. |

| A little RCBS Partner press as I received it. |

| Another shot of the Partner, notice the shellholder beside it. |

| Look at how nasty the ram and frame is. Again all the metal parts came out shiny and bright. Unfortunately, I didn't think to take pics after I finished. |

| The shellholder that was on the Partner. Note the name RCBS and the number (6) is stamped on the top, this must be very old, the current shellholders are stamped on the back edge. |

| An RCBS Uniflow powder measure. |

| Close up, as I soaked it in WD-40. The cylender was really nasty. |

| Kyle found this at a gun show, it was in moderate condition. This is how it cleaned up Note it came with an automatic primer device but the tube is missing. |

|

| Still not great but a lot better, all the metal surfaces are clean and rust free. |

| You can see here how the handle and toggle block brushed up. |

| All the parts, note I didn't remove the ram toggle link from the toggle block. |

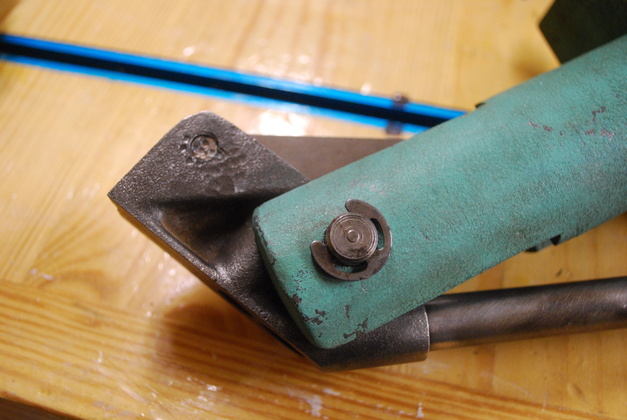

| Close up of the toggle block, note some former owner has staked in the pin holding the toggle link into the toggle block. |

| Back together. |

| You can still see the peen marks on the toggle block link pin. |

| The auto prime mechanism (without tube). This unit will need a small primer plug, and both large and small primer tubes. |

| Primer arm in position to insert primer. |