Mounting a Rifle Scope ( Correctly )

Mounting a scope can be a much bigger job than most shooters realize.

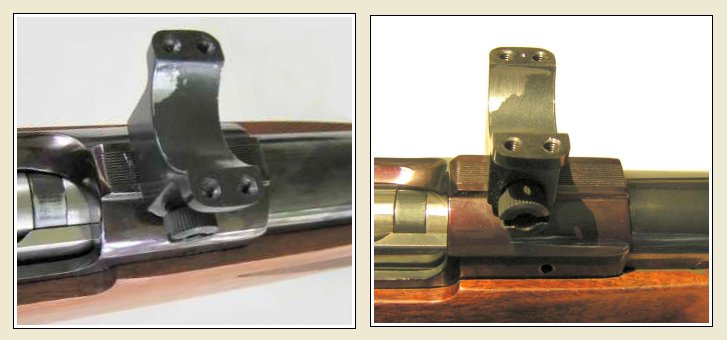

This is a left-handed Ruger Model 77 Mark ll (.270 Win.) that I

built for a friend. He wanted to use a 3.5

-10X Leupold scope with a 50 mm front lens. That required taller

scope rings. Then it needed a stock with a higher cheek piece to

enable a comfortable shooting position. I inletted, glass

bedded, and finished this custom stock. This stock received the

full treatment (minus the checkering). I set the trigger just

under 2.5 pounds, and then I mounted the scope.

You can see that the eye relief on this rig can

only be corrected by some slight adjusting of the stock dimensions.

There's a lot to consider when mounting a rifle scope.

Some shooters think that the onlt consideration is the bolt clearance

at the rear of the scope. That's only part of the story.

Left-handed rifles usually look weird to me, so I've reversed the next

few pictures of this same rifle to make things look better, and I'll

show you the best way to mount a rifle scope securely.

( Left-handed shooters . . . . use your imagination. )