Understanding Headspace

. . . . the rest of the story

The

term headspace means the "space" between the "head" of your case and

the breech. This space is set by the firearm manufacturer.

It should to be the minimum clearance to prevent your cartridge

from being pushed forward when the primer gets hit by the firing pin.

Factory "belted" ammo is designed to have the belt stop any

forward movement of the case. Factory "rimmed" ammo is designed

to have the rim stop any forward movement of the case. Factory

"non-rimmed" ammo is designed to have the case shoulder stop any

forward movement of the case. Of course there are some

exceptions with pistol calibers.

Most handloaders understand that handloads should

always have the minimum chamber clearance (at the shoulder).

This is true when reloading any rifle cartridge. Most reloaders

commonly refer to this chamber clearance as "headspace". The

concept is correct, but technically speaking the term "headspace" here

actually makes things a bit confusing. For handloading purposes,

the term headspace means any chamber clearance that allows your

cartridge to move or expand forward. When handloading a

non-rimmed rifle case, the reloader can simply be concerned with

maintaining minimum chamber clearance at the shoulder.

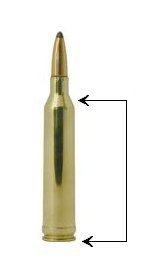

The picture at the left shows where to measure

chamber clearance when comparing your handloads to a fired case.

This length needs to be resized just short enough to ensure a reliable

fit in your chamber. It also needs to be long enough to prevent

the brass from stretching when it is fired. If there is too much

chamber clearance (at the shoulder), cases can stretch far enough to

crack at the expansion ring. These cracks are a sign of serious

(sometimes dangerous) headspace problems. During firing, cases

expand tightly against the chamber wall. This seals the high

chamber pressure during firing and prevents hot gas from blowing back

through the action. If a case ruptures it can be a safety hazard

for the shooter and for bystanders.

The picture at the left shows where to measure

chamber clearance when comparing your handloads to a fired case.

This length needs to be resized just short enough to ensure a reliable

fit in your chamber. It also needs to be long enough to prevent

the brass from stretching when it is fired. If there is too much

chamber clearance (at the shoulder), cases can stretch far enough to

crack at the expansion ring. These cracks are a sign of serious

(sometimes dangerous) headspace problems. During firing, cases

expand tightly against the chamber wall. This seals the high

chamber pressure during firing and prevents hot gas from blowing back

through the action. If a case ruptures it can be a safety hazard

for the shooter and for bystanders.

The enlarged picture at the right shows a cutaway

view of a belted magnum case that has been reloaded with excessive

chamber clearance at the shoulder. You can see inside the case,

where it has been stretched to the point that it is now very thin.

The arrows show where the case stretching is the worst - at the

expansion ring. If a case is going to crack from a headspace

problem, this is where it will occur. Cases with this much wear

should be discarded, because they are likely to crack or even rupture

on the next firing. You should always examine this area inside

your cases before reloading. Some handloaders use a sharpened

spring hook or even a paperclip to reach in and "feel" the amount of

wear in this area.

Headspace separation is much more common with

belted magnum calibers. This is because ammunition manufacturers

always make their belted magnum loads to headspace on the belt.

They also leave the shoulder extremely far from contacting the chamber.

This causes the first firing of belted cases to stretch quite

badly. Your "once fired" case is now stretched considerably, and

it is weakened at the expansion ring. The good news is that

further case damage can be kept to a minimum when handloading by

controlling chamber clearance at the shoulder, just as you would for

any rimless caliber. Our Belted Magnum Collet Resizing Die

avoids thinning your brass by resizing the case directly inward, and

then only when a little extra resizing is required.

Headspace separation is much more common with

belted magnum calibers. This is because ammunition manufacturers

always make their belted magnum loads to headspace on the belt.

They also leave the shoulder extremely far from contacting the chamber.

This causes the first firing of belted cases to stretch quite

badly. Your "once fired" case is now stretched considerably, and

it is weakened at the expansion ring. The good news is that

further case damage can be kept to a minimum when handloading by

controlling chamber clearance at the shoulder, just as you would for

any rimless caliber. Our Belted Magnum Collet Resizing Die

avoids thinning your brass by resizing the case directly inward, and

then only when a little extra resizing is required.

The only rifle cartridges

that ever actually required a belt are the .300 H&H Magnum and the

.375 H&H Magnum. Because of their extremely shallow shoulder

angle, these two calibers actually need a belt to prevent the case from

being pushed forward. As you can see on the cutaway case, the

belt is located around the "solid" portion of the case, and it

obviously adds no strength to the case whatsoever. In the

decades that followed, the belt was added to over 20 different calibers

purely for marketing reasons. Firearm manufacturers figured that

if any new magnum caliber didn't have a belt (like the H&H cases)

it would never sell. In fact . . . .

if these 2 calibers weren't such incredible performers (in the early

days) there wouldn't be ANY magnum calibers using a belt today.

Most shooters that reload belted magnums notice a

slight case bulge that forms "just above" the belt. This usually

happens after just 2 or 3 reloadings - wasting perfectly good cases.

Many shooters first assume that their cases aren't getting

resized enough when their handloads begin to stick or even fail to

chamber. Their first thought is that these cases must be too

long. However, it's easy to prove that it's really a case

"width" problem just above the belt. This problem is now easy to

resolve with our Belted Magnum Collet Resizing Die.

In order to resize the body on most belted cases,

your resizing die needs to firmly contact the case, and then forcibly

squeeze downward almost .100" beyond that point. This is required just to reduce .001"

from the diameter of a tapered case. The brass gets plowed

rearward against the belt, preventing any conventional resizing die

from traveling far enough down the case. As the case is

withdrawn, the brass also "springs back" slightly. That's why I

invented the Belted Magnum Collet Resizing Die - to only compress the

brass inward. This ensures a reliable, perfect fit in your

chamber, and it extends the life of your cases.

The case bulge problem is made even worse by reloaders

that don't reduce their chamber clearance at the shoulder. When

a case is fired, it stretches to fill your chamber. This

excessive stretching also weakens your case - just above the belt.

You can read all about our Belted Magnum Collet Resizing Die and our Digital Headspace Gauge on our homepage. These tools both help ensure a reliable fit in your chamber, and provide much longer case life.