Arduino Metal Detector #1

From: https://www.allaboutcircuits.com/projects/metal-detector-with-arduino/

github: https://github.com/evankale/ArduinoMetalDetector

Build Your Own Metal Detector with an Arduino

October 03, 2016 by Evan Kale

Building a metal detector using a Colpitts oscillator and an Arduino.

Learn how to build a metal detector using a Colpitts oscillator and an Arduino.

How Do Metal Detectors Work?

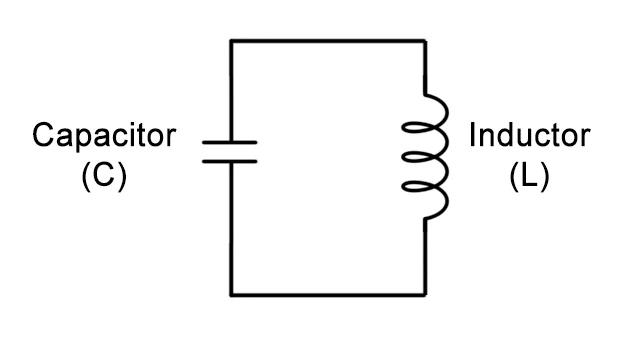

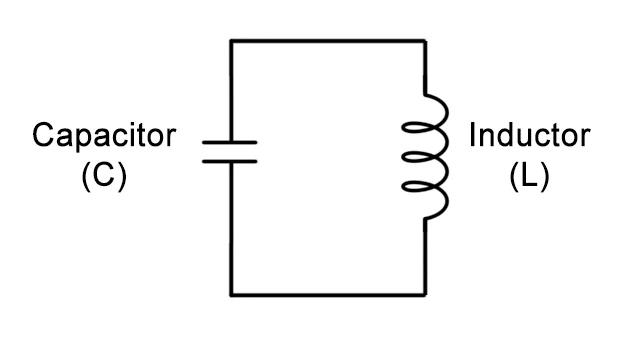

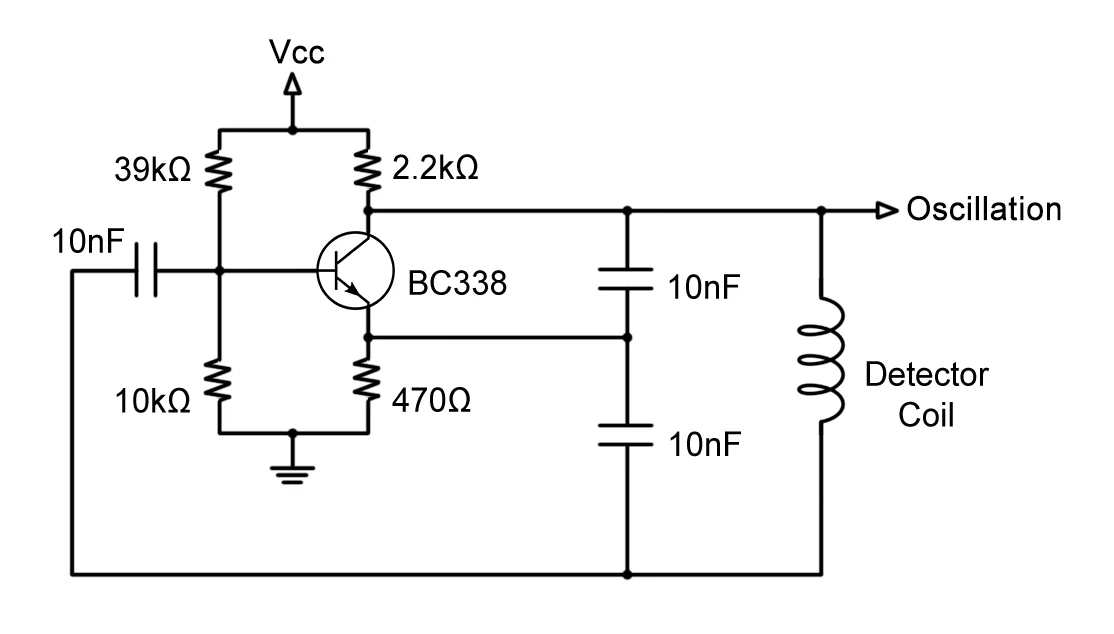

Tank circuit

The tank circuit

In the above circuit, the series capacitor and inductor form a tank circuit.

In a tank circuit, energy is transferred repeatedly between a capacitor and

an inductor, resulting in oscillation. Current discharged from the capacitor

flows through the inductor; when the capacitor is completely discharged, the

inductor's decreasing magnetic field maintains the current flow. The

capacitor will then charge with the opposite polarity, and when the magnetic

field has completely collapsed, the capacitor will discharge, resulting in

current flow in the direction opposite to that of the original current.

This cycle continues.

The inductor of the above tank circuit forms the detector of the metal

detector( a large coil of wire). When metallic material approaches the

center of the inductor( the detector coil), it enters the magnetic field

created by the inductor. This changes the magnetic permeability of the

inductor’s core, causing the inductance to change. The change in

inductance, in turn, changes the oscillating frequency of the tank circuit.

If the components were ideal, the tank circuit would oscillate indefinitely

without an external power source. But, in practice, the components are non

-ideal. The unwanted resistance of the components will introduce energy

loss, causing the oscillating current to taper to a stop. To counter this, a

single stage BJT inverting amplifier is used to continuously add gain into

the tank circuit.

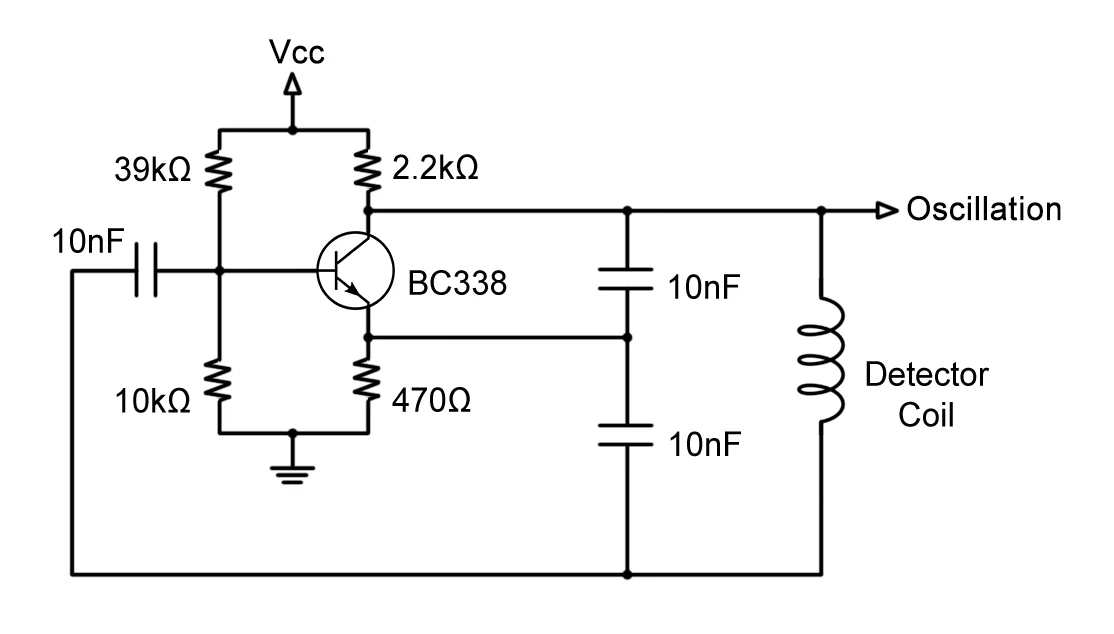

Colpitts oscillator

The tank circuit

In the above circuit, the series capacitor and inductor form a tank circuit.

In a tank circuit, energy is transferred repeatedly between a capacitor and

an inductor, resulting in oscillation. Current discharged from the capacitor

flows through the inductor; when the capacitor is completely discharged, the

inductor's decreasing magnetic field maintains the current flow. The

capacitor will then charge with the opposite polarity, and when the magnetic

field has completely collapsed, the capacitor will discharge, resulting in

current flow in the direction opposite to that of the original current.

This cycle continues.

The inductor of the above tank circuit forms the detector of the metal

detector( a large coil of wire). When metallic material approaches the

center of the inductor( the detector coil), it enters the magnetic field

created by the inductor. This changes the magnetic permeability of the

inductor’s core, causing the inductance to change. The change in

inductance, in turn, changes the oscillating frequency of the tank circuit.

If the components were ideal, the tank circuit would oscillate indefinitely

without an external power source. But, in practice, the components are non

-ideal. The unwanted resistance of the components will introduce energy

loss, causing the oscillating current to taper to a stop. To counter this, a

single stage BJT inverting amplifier is used to continuously add gain into

the tank circuit.

Colpitts oscillator

The Colpitts oscillator

Since the oscillation at the nodes before and after the inductor are 180°

out of phase of with each other, one of the nodes will supply the

oscillation to the transistor base, amplify and invert the signal at the

collector, then return it in phase to the other node of the tank circuit.

This entire circuit is called the Colpitts oscillator.

The Colpitts oscillator above provides a steady oscillation with a frequency

in the 100kHz range. Metals from household items changing the permeability

of the inductor core will fluctuate this frequency around 10kHz. Since this

frequency range is outside of the human audio spectrum( 20Hz to 20kHz), we

will need to translate the oscillation into an audible tone.

Traditional BFO( beat-frequency oscillator) metal detectors overcome this

problem by incorporating another tank circuit with a fixed frequency equal

to the frequency of the detector tank circuit without the influence of any

metals. Then, taking the difference between the two frequencies will isolate

the fluctuating frequencies of the detector circuit and bring it down to an

audible range.

For this metal detector project, we will be using an Arduino to process the

oscillation signal instead of offsetting the oscillation with a second tank

circuit. The Arduino will store the fixed frequency and continuously compare

the incoming frequency of the detector circuit with the stored frequency

(more on the Arduino program below).

The Colpitts oscillator

Since the oscillation at the nodes before and after the inductor are 180°

out of phase of with each other, one of the nodes will supply the

oscillation to the transistor base, amplify and invert the signal at the

collector, then return it in phase to the other node of the tank circuit.

This entire circuit is called the Colpitts oscillator.

The Colpitts oscillator above provides a steady oscillation with a frequency

in the 100kHz range. Metals from household items changing the permeability

of the inductor core will fluctuate this frequency around 10kHz. Since this

frequency range is outside of the human audio spectrum( 20Hz to 20kHz), we

will need to translate the oscillation into an audible tone.

Traditional BFO( beat-frequency oscillator) metal detectors overcome this

problem by incorporating another tank circuit with a fixed frequency equal

to the frequency of the detector tank circuit without the influence of any

metals. Then, taking the difference between the two frequencies will isolate

the fluctuating frequencies of the detector circuit and bring it down to an

audible range.

For this metal detector project, we will be using an Arduino to process the

oscillation signal instead of offsetting the oscillation with a second tank

circuit. The Arduino will store the fixed frequency and continuously compare

the incoming frequency of the detector circuit with the stored frequency

(more on the Arduino program below).

Materials for your DIY Metal Detector

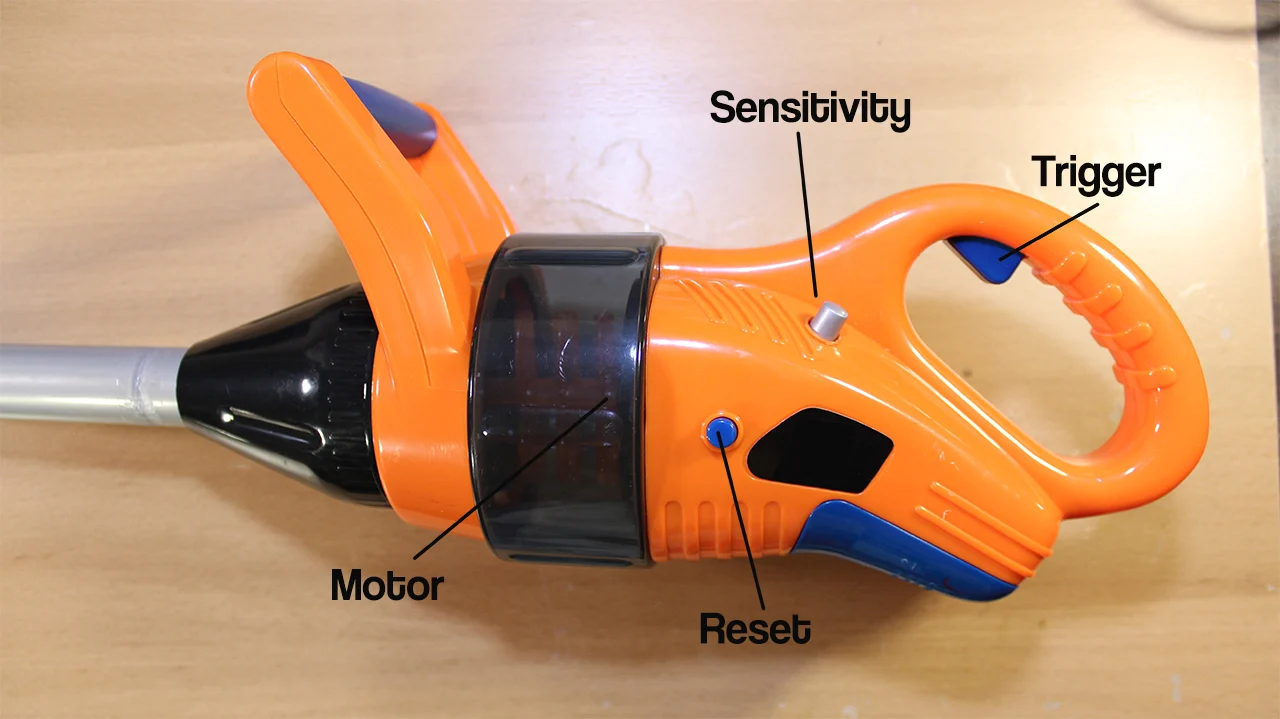

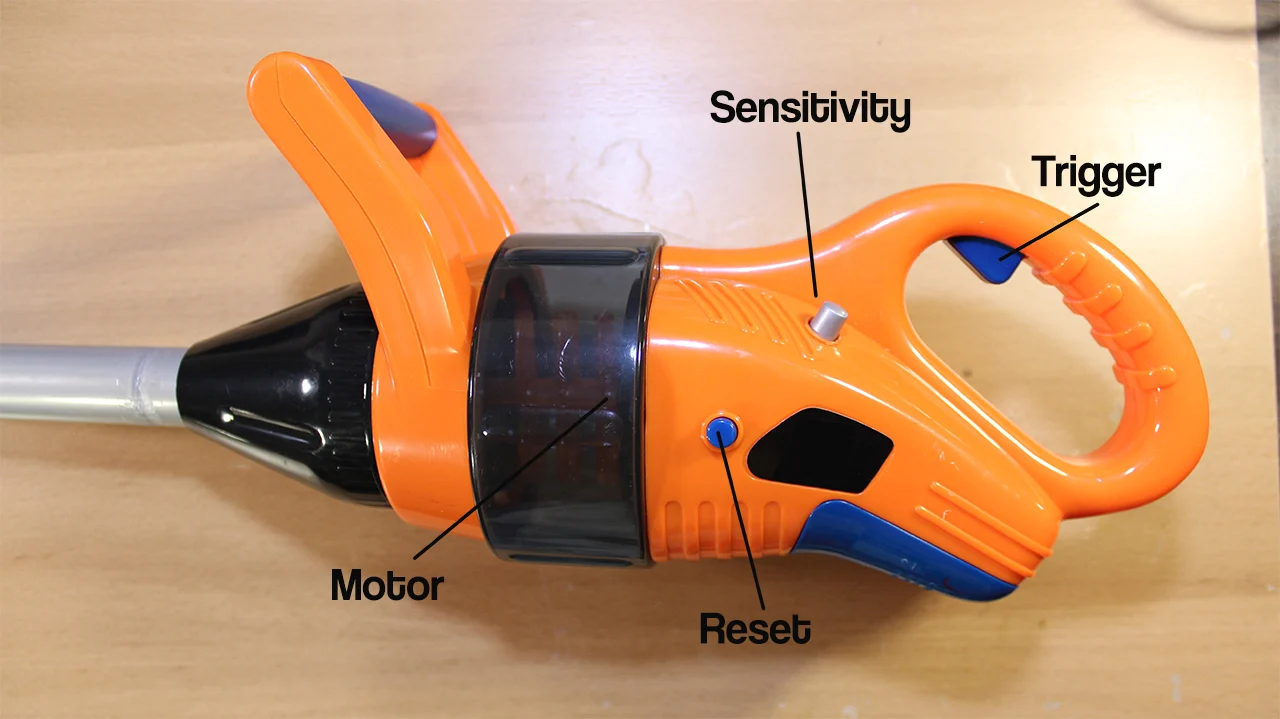

Weed-whacker toy

For this project, a toy weed-whacker was chosen to house all the components.

It includes the following features:

Weed-whacker toy

For this project, a toy weed-whacker was chosen to house all the components.

It includes the following features:

- a trigger button, which we will repurpose to trigger the speaker

- a side button, which we will use to set the fixed frequency

- a battery compartment( 3xAA batteries) with an ON/OFF switch

- a speaker, which we will play the tone through

- a motor with LEDs attached which we will be activated when the frequency

difference exceeds a certain threshold

- a circular head where we will fit a coil of wire into for the inductor of

the tank circuit

We will also add a potentiometer (silver) to make the sensitivity of the tone

changes adjustable.

Detector coil

The inductor coil is made from approximately 50 wraps of 26 AWG wire around

a spool of 5.5 inches in diameter.

Detector coil

The inductor coil is made from approximately 50 wraps of 26 AWG wire around

a spool of 5.5 inches in diameter.

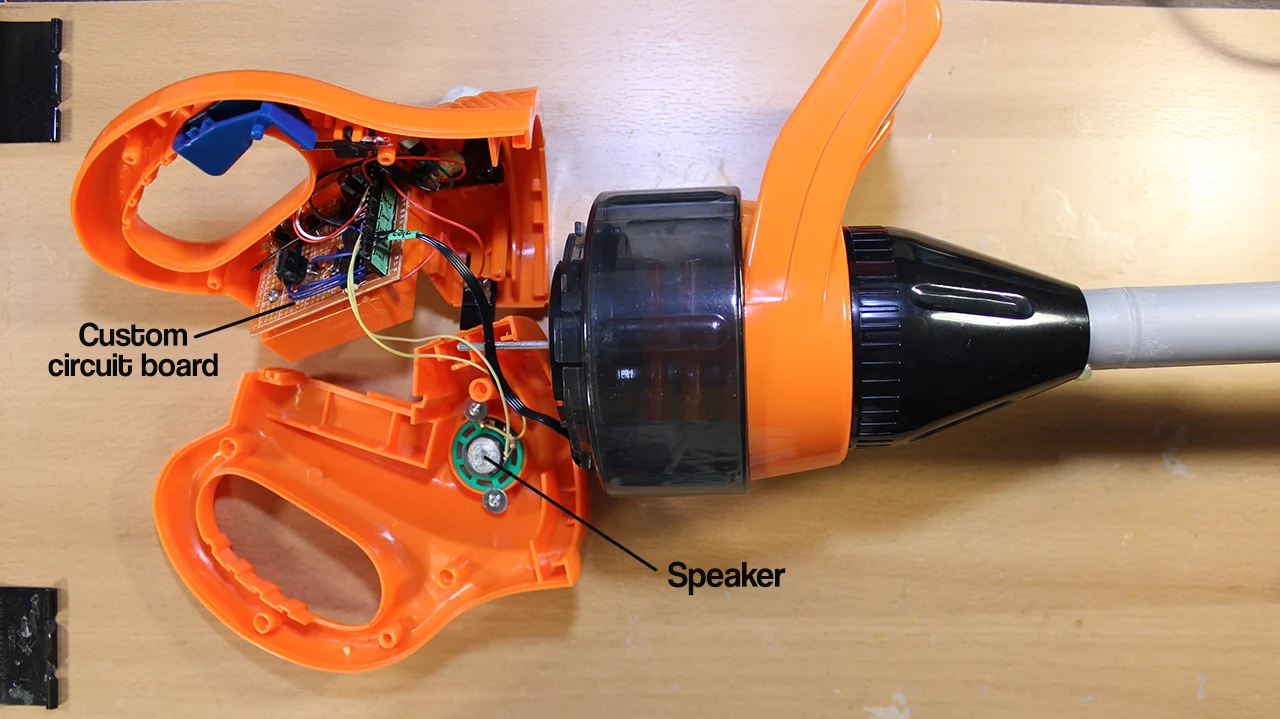

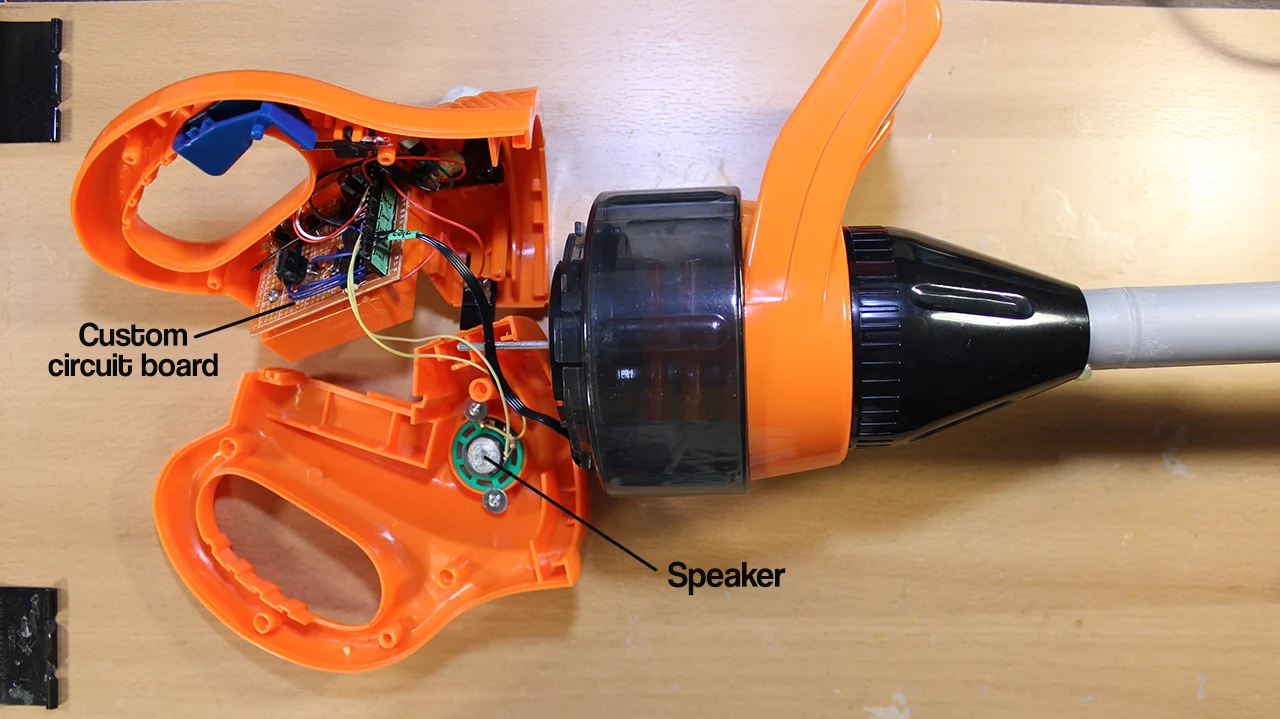

Inside the housing

Inside the housing, we will replace the original circuit board with our own

circuit and attach all the peripherals to the circuit with pin headers.

Inside the housing

Inside the housing, we will replace the original circuit board with our own

circuit and attach all the peripherals to the circuit with pin headers.

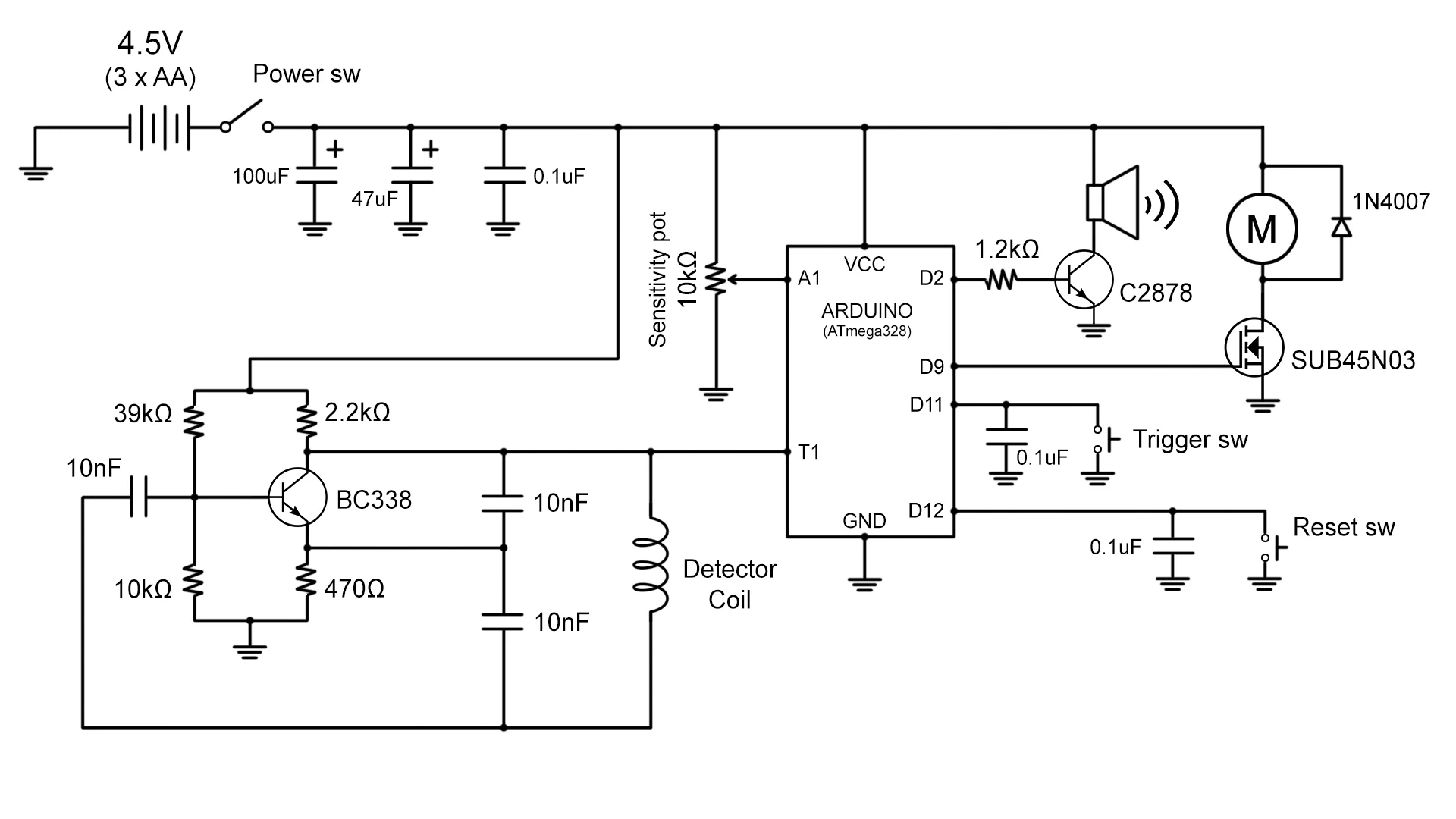

Metal Detection Circuit Schematics

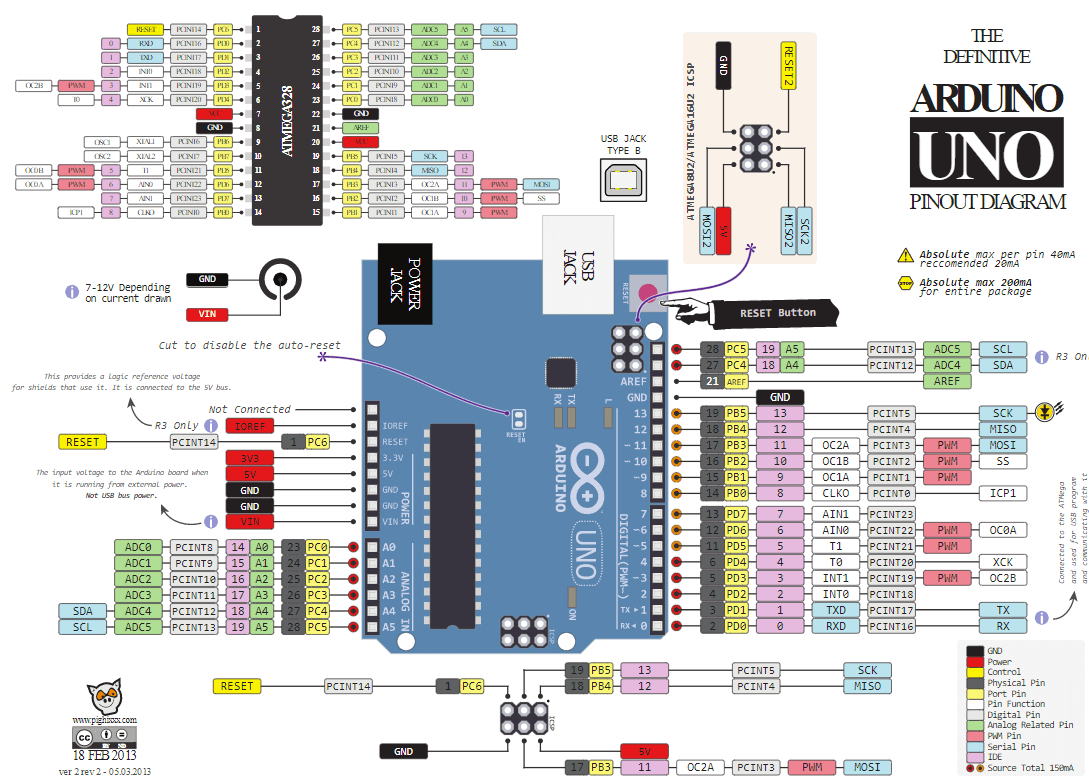

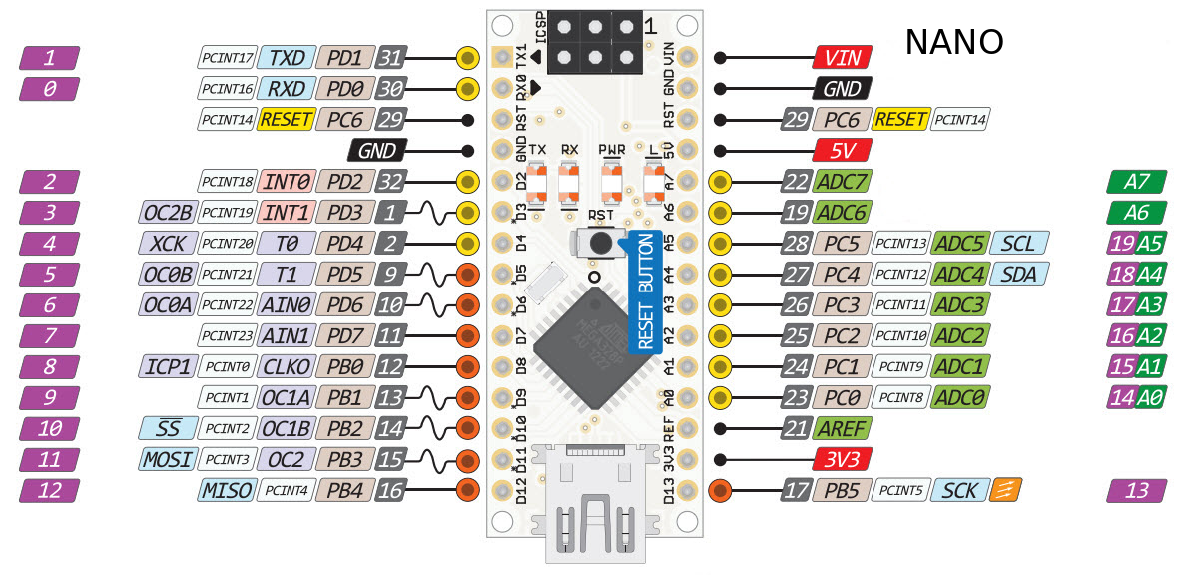

I used an Arduino UNO to program a DIP ATMega328. I then removed the

ATMega328 from the development board and embedded into a perfboard along

with the rest of the circuit.

The Colpitts oscillator, on the bottom left on the diagram, feeds the

oscillation into counter 1( pin T1) of the chip( marked as digital pin 5 on

the Arduino UNO), where it constantly counts the frequency of oscillation.

On the top level of the diagram, a power supply of 4.5V( 3xAA batteries,

with bypass capacitors) is used to power the ATmega328, oscillator, speaker,

and motor( with LEDs).

To keep the current draw of the microcontroller’s digital pins at a safe

level( 40 mA per pin maximum for the ATmega328), an NPN transistor( C2878)

is used to drive the speaker, and an N-channel MOSFET( SUB45N03) to drive

the motor.

Both the trigger and reset( sets fixed frequency) switches are wired to

digital pins using internal pull-up configuration. Small capacitors are

added in parallel to debounce the switches.

The sensitivity potentiometer is set up as a voltage divider, and the

division is read using an analog pin.

Code Walkthrough

The full source code for this project can be found here:

Below is a detailed walkthrough of the code.

Setup Function

To keep track of the detector oscillation frequency through timer counter 1,

we first need to configure the timer/counter controller registers (TCCR).

These TCCRs are accessed through the three integers: TTCR1A, TTCR1B, and TTCR1C.

TCCR1A = 0b00000000;

TCCR1B = 0b00000111;

We will need to set the waveform generation to normal mode by setting the

WGM flags of TCCR1A and TCCR1B to 0, and set the clock speed selection mode

to external clock source by setting CS flags of TCCR1B to mode 3 (external

clock on rising edge). In this configuration, the register OCR1A will

decrement by 1 every time a rising edge is detected from the oscillation.

TIMSK1 |= (1 << OCIE1A);

Next we'll need to enable timer/count interrupt A by setting the OCIE1A flag

in TIMSK1 register. This will enable the SIGNAL( TIMER1_COMPA_vect ) interrupt

function to be called whenever OCR1A register reaches 0.

OCR1A = 1;

Now initialize OCR1A to 1 so that the interrupt function is called as soon

as the first rising edge is detected.

Interrupt Function

This is the SIGNAL( TIMER1_COMPA_vect ) function. It's called when the OCR1A

register reaches 0. In this function, we want to keep track of the number of

microseconds elapsed since the last time the function was called. This time

delta is stored as signalTimeDelta.

storedTimeDelta is the “fixed frequency” time delta that signalTimeDelta

is compared to in the main loop. storedTimeDelta is set to signalTimeDelta

when storedTimeDelta is zeroed (on bootup and when the reset switch is pressed).

OCR1A += CYCLES_PER_SIGNAL;

After performing interrupt operations, OCR1A needs to be reset by

incrementing it with our predefined constant, CYCLES_PER_SIGNAL (number of

cycles before next interrupt occurs).

Loop Function

In the loop function, we check if the trigger is pressed. If so, then read

the analog value of the sensitivity potentiometer and linearly interpolate

the analog value (0 to 1023) to an easier to use scale (0.5 to 10.0).

int storedTimeDeltaDifference = (storedTimeDelta - signalTimeDelta) *sensitivity;

The difference between the fixed frequency (storedTimeDelta) and measured

frequency (signalTimeDelta) is calculated and multiplied by the sensitivity

value.

tone( SPEAKER_PIN, BASE_TONE_FREQUENCY + storedTimeDeltaDifference);

This value is then summed with an audible base tone frequency,

BASE_TONE_FREQUENCY, and played out the speaker using the Arduino tone() function.

If the difference exceeds the threshold defined by SPINNER_THRESHOLD, then

the motor is activated.

If the trigger is released, then the speaker tone is stopped (by calling

noTone() function) and the motor is deactivated.

If the reset button has been pressed, it will zero storedTimeDelta, allowing

the next interrupt call to set a new value.

Sketch

ArduinoMetalDetector-master.zip

===========================================================================

/********************************************************

* Copyright( c) 2016 Evan Kale

* Media: @EvanKale91

* Email: EvanKale91@gmail.com

* Website: www.ISeeDeadPixel.com www.evankale.blogspot.ca www.youtube.com/EvanKale91

* This file is part of ArduinoMetalDetector.

* ArduinoMetalDetector is free software: you can redistribute it and/or modify

* it under the terms of the GNU General Public License as published by

* the Free Software Foundation, either version 3 of the License, or

*( at your option) any later version.

* This program is distributed in the hope that it will be useful,

* but WITHOUT ANY WARRANTY; without even the implied warranty of

* MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

* GNU General Public License for more details.

* You should have received a copy of the GNU General Public License

* along with this program. If not, see .

********************************************************/

// **************** DEFINES ****************************

#define CYCLES_PER_SIGNAL 5000 // NMBR CYCLES TO GENERATE SIGNAL EVENT

#define BASE_TONE_FREQUENCY 280 // BASE TONE FREQUENCY(SPEAKER)

#define SPINNER_THRESHOLD 700 // FREQ DELTA THRESHOLD FOR SPINNER TO TRIGGER

#define SENSITIVITY_POT_APIN 1 // PIN DEFINITIONS

#define SPEAKER_PIN 2

#define SPINNER_PIN 9

#define TRIGGER_BTN_PIN 11

#define RESET_BTN_PIN 12

typedef unsigned long ulong;

// **************** PROTOTYPES *************************

SIGNAL( TIMER1_COMPA_vect );

float mapFloat( int input, int inMin, int inMax, float outMin, float outMax);

// **************** VARIABLES **************************

ulong lastSignalTime = 0;

ulong signalTimeDelta = 0;

boolean firstSignal = true;

ulong s toredTimeDelta = 0;

/*F*******************************************************

*

*********************************************************/

void

setup()

{

TCCR1A = 0b00000000; // SET WGM(Waveform Generation Mode) to 0( Normal)

// SET CSS(CLOCK SPEED SELECTION) TO 0b111( EXTERNAL CLOCK SOURCE ON T0 PIN

//( IE, PIN 5 ON UNO). CLOCK ON RISING EDGe.)

TCCR1B = 0b00000111;

TIMSK1 |= (1 << OCIE1A); // ENABLE TIMER COMPARE INTERRUPT A( ie, SIGNAL(TIMER1_COMPA_VECT))

OCR1A = 1; // SET OCR1A( TIMER A COUNTER) TO 1 TO TRIGGER INTERRUPT ON NEXT CYCLE

pinMode( SPEAKER_PIN, OUTPUT );

pinMode( SPINNER_PIN, OUTPUT );

pinMode( TRIGGER_BTN_PIN, INPUT_PULLUP );

pinMode( RESET_BTN_PIN, INPUT_PULLUP );

}

/*F*******************************************************

*

*********************************************************/

void

loop()

{

if( digitalRead( TRIGGER_BTN_PIN) == LOW)

{

float sensitivity = mapFloat( analogRead( SENSITIVITY_POT_APIN), 0

, 1023, 0.5, 10.0);

int storedTimeDeltaDifference = (storedTimeDelta - signalTimeDelta )

* sensitivity;

tone( SPEAKER_PIN, BASE_TONE_FREQUENCY + storedTimeDeltaDifference );

if( storedTimeDeltaDifference > SPINNER_THRESHOLD )

{

digitalWrite( SPINNER_PIN, HIGH);

}

else

{

digitalWrite( SPINNER_PIN, LOW);

}

}

else

{

noTone( SPEAKER_PIN );

digitalWrite( SPINNER_PIN, LOW );

}

if( digitalRead( RESET_BTN_PIN) == LOW)

{

storedTimeDelta = 0;

}

}

/*F*******************************************************

*

*********************************************************/

float

mapFloat( int input, int inMin, int inMax, float outMin, float outMax)

{

float scale = (float)(input - inMin) /( inMax - inMin);

return( (outMax - outMin) * scale) + outMin;

}

/*F*******************************************************

* THIS SIGNAL IS CALLED WHENEVER OCR1A REACHES 0

Note: OCR1A IS DECREMENTED ON EVERY EXTERNAL CLOCK CYCLE)

*********************************************************/

SIGNAL( TIMER1_COMPA_vect )

{

ulong currentTime = micros();

signalTimeDelta = currentTime - lastSignalTime;

lastSignalTime = currentTime;

if( firstSignal)

{

firstSignal = false;

}

else if( storedTimeDelta == 0)

{

storedTimeDelta = signalTimeDelta;

}

// Reset OCR1A

OCR1A += CYCLES_PER_SIGNAL;

}

===========================================================================

How Functional is Our Arduino-Based Metal Detector?

With the lowest sensitivity setting, the metal detector can pick up large

items like soda cans, cell phones, and iron tools within a few inches away

from the coil. On the highest sensitivity setting, smaller items like steel

rings, screws, and coins within the same proximity can also be detected. See

the video at the top of the article for a demonstration!

To extend the range of the detector, we can increase the magnetic field area

created by the inductor. This can be achieved by increasing the current flow

through the inductor( by increasing voltage input to the oscillator,

allowing a greater gain in the amplifier), or by increasing the number of

wire wraps in the inductor coil.

With an Arduino-based metal detector, we can do other interesting things

that cannot be done with traditional BFO metal detectors. Stay tuned for

future projects on how we can take advantage of this metal detecting

mechanism for other purposes!

Give this project a try for yourself! Get the BOM.

Content From Partners

Renesas’ RealityCheck™ Motor Software Toolbox

Content from Renesas Electronics

Related Content

The tank circuit

In the above circuit, the series capacitor and inductor form a tank circuit.

In a tank circuit, energy is transferred repeatedly between a capacitor and

an inductor, resulting in oscillation. Current discharged from the capacitor

flows through the inductor; when the capacitor is completely discharged, the

inductor's decreasing magnetic field maintains the current flow. The

capacitor will then charge with the opposite polarity, and when the magnetic

field has completely collapsed, the capacitor will discharge, resulting in

current flow in the direction opposite to that of the original current.

This cycle continues.

The inductor of the above tank circuit forms the detector of the metal

detector( a large coil of wire). When metallic material approaches the

center of the inductor( the detector coil), it enters the magnetic field

created by the inductor. This changes the magnetic permeability of the

inductor’s core, causing the inductance to change. The change in

inductance, in turn, changes the oscillating frequency of the tank circuit.

If the components were ideal, the tank circuit would oscillate indefinitely

without an external power source. But, in practice, the components are non

-ideal. The unwanted resistance of the components will introduce energy

loss, causing the oscillating current to taper to a stop. To counter this, a

single stage BJT inverting amplifier is used to continuously add gain into

the tank circuit.

Colpitts oscillator

The tank circuit

In the above circuit, the series capacitor and inductor form a tank circuit.

In a tank circuit, energy is transferred repeatedly between a capacitor and

an inductor, resulting in oscillation. Current discharged from the capacitor

flows through the inductor; when the capacitor is completely discharged, the

inductor's decreasing magnetic field maintains the current flow. The

capacitor will then charge with the opposite polarity, and when the magnetic

field has completely collapsed, the capacitor will discharge, resulting in

current flow in the direction opposite to that of the original current.

This cycle continues.

The inductor of the above tank circuit forms the detector of the metal

detector( a large coil of wire). When metallic material approaches the

center of the inductor( the detector coil), it enters the magnetic field

created by the inductor. This changes the magnetic permeability of the

inductor’s core, causing the inductance to change. The change in

inductance, in turn, changes the oscillating frequency of the tank circuit.

If the components were ideal, the tank circuit would oscillate indefinitely

without an external power source. But, in practice, the components are non

-ideal. The unwanted resistance of the components will introduce energy

loss, causing the oscillating current to taper to a stop. To counter this, a

single stage BJT inverting amplifier is used to continuously add gain into

the tank circuit.

Colpitts oscillator

The Colpitts oscillator

Since the oscillation at the nodes before and after the inductor are 180°

out of phase of with each other, one of the nodes will supply the

oscillation to the transistor base, amplify and invert the signal at the

collector, then return it in phase to the other node of the tank circuit.

This entire circuit is called the Colpitts oscillator.

The Colpitts oscillator above provides a steady oscillation with a frequency

in the 100kHz range. Metals from household items changing the permeability

of the inductor core will fluctuate this frequency around 10kHz. Since this

frequency range is outside of the human audio spectrum( 20Hz to 20kHz), we

will need to translate the oscillation into an audible tone.

Traditional BFO( beat-frequency oscillator) metal detectors overcome this

problem by incorporating another tank circuit with a fixed frequency equal

to the frequency of the detector tank circuit without the influence of any

metals. Then, taking the difference between the two frequencies will isolate

the fluctuating frequencies of the detector circuit and bring it down to an

audible range.

For this metal detector project, we will be using an Arduino to process the

oscillation signal instead of offsetting the oscillation with a second tank

circuit. The Arduino will store the fixed frequency and continuously compare

the incoming frequency of the detector circuit with the stored frequency

(more on the Arduino program below).

The Colpitts oscillator

Since the oscillation at the nodes before and after the inductor are 180°

out of phase of with each other, one of the nodes will supply the

oscillation to the transistor base, amplify and invert the signal at the

collector, then return it in phase to the other node of the tank circuit.

This entire circuit is called the Colpitts oscillator.

The Colpitts oscillator above provides a steady oscillation with a frequency

in the 100kHz range. Metals from household items changing the permeability

of the inductor core will fluctuate this frequency around 10kHz. Since this

frequency range is outside of the human audio spectrum( 20Hz to 20kHz), we

will need to translate the oscillation into an audible tone.

Traditional BFO( beat-frequency oscillator) metal detectors overcome this

problem by incorporating another tank circuit with a fixed frequency equal

to the frequency of the detector tank circuit without the influence of any

metals. Then, taking the difference between the two frequencies will isolate

the fluctuating frequencies of the detector circuit and bring it down to an

audible range.

For this metal detector project, we will be using an Arduino to process the

oscillation signal instead of offsetting the oscillation with a second tank

circuit. The Arduino will store the fixed frequency and continuously compare

the incoming frequency of the detector circuit with the stored frequency

(more on the Arduino program below).

Weed-whacker toy

For this project, a toy weed-whacker was chosen to house all the components.

It includes the following features:

Weed-whacker toy

For this project, a toy weed-whacker was chosen to house all the components.

It includes the following features: Detector coil

The inductor coil is made from approximately 50 wraps of 26 AWG wire around

a spool of 5.5 inches in diameter.

Detector coil

The inductor coil is made from approximately 50 wraps of 26 AWG wire around

a spool of 5.5 inches in diameter.

Inside the housing

Inside the housing, we will replace the original circuit board with our own

circuit and attach all the peripherals to the circuit with pin headers.

Inside the housing

Inside the housing, we will replace the original circuit board with our own

circuit and attach all the peripherals to the circuit with pin headers.