Capacitor Types

From: https://www.electronics-tutorials.ws/capacitor/cap_2.html

Types of Capacitor

|

Types of Capacitor

There is a large variety of different types of capacitor

available in the market place and each one has its own set

of characteristics and applications

|

The types of capacitor available range from very small delicate trimming

capacitors using in oscillator or radio circuits, up to large power metal-can

type capacitors used in high voltage power correction and smoothing circuits.

The comparisons between the the different types of capacitor is generally made

with regards to the dielectric used between the plates. Like resistors, there

are also variable types of capacitors which allow us to vary their capacitance

value for use in radio or “frequency tuning” type circuits.

Commercial types of capacitors are made from metallic foil interlaced with thin

sheets of either paraffin-impregnated paper or Mylar as the dielectric material.

Some capacitors look like tubes, this is because the metal foil plates are

rolled up into a cylinder to form a small package with the insulating

dielectric material sandwiched in between them.

Small capacitors are often constructed from ceramic materials and then dipped

into an epoxy resin to seal them. Either way, capacitors play an important part

in electronic circuits so here are a few of the more “common” types of capacitor

available.

Dielectric Capacitor

Dielectric Capacitors are usually of the variable type were a continuous

variation of capacitance is required for tuning transmitters, receivers and

transistor radios. Variable dielectric capacitors are multi-plate air-spaced

types that have a set of fixed plates (the stator vanes) and a set of

movable plates (the rotor vanes) which move in between the fixed plates.

The position of the moving plates with respect to the fixed plates

determines the overall capacitance value. The capacitance is generally at

maximum when the two sets of plates are fully meshed together. High voltage

type tuning capacitors have relatively large spacings or air-gaps between

the plates with breakdown voltages reaching many thousands of volts.

Variable Capacitor Symbol

variable capacitor symbol

As well as the continuously variable types of capacitor, preset type

variable capacitors are also available called Trimmers. These are generally

small devices that can be adjusted or “pre-set” to a particular

capacitance value with the aid of a small screwdriver and are available in

very small capacitance’s of 500pF or less and are non-polarized.

variable capacitor symbol

As well as the continuously variable types of capacitor, preset type

variable capacitors are also available called Trimmers. These are generally

small devices that can be adjusted or “pre-set” to a particular

capacitance value with the aid of a small screwdriver and are available in

very small capacitance’s of 500pF or less and are non-polarized.

Film Capacitor Type

Film Capacitors are the most commonly available of all types of capacitor,

consisting of a relatively large family of capacitors with the difference

being in their dielectric properties. These include polyester (Mylar),

polystyrene, polypropylene, polycarbonate, metalised paper, Teflon etc.

Film types of capacitor are available in capacitance ranges from as small as 5pF

to as large as 100uF depending upon the actual type of capacitor and its

voltage rating. Film capacitors also come in an assortment of shapes and

case styles which include:

- Wrap & Fill (Oval & Round) – where the capacitor is wrapped in a

tight plastic tape and have the ends filled with epoxy to seal them.

- Epoxy Case (Rectangular & Round) – where the capacitor is encased in

a moulded plastic shell which is then filled with epoxy.

- Metal Hermetically Sealed (Rectangular & Round) – where the

capacitor is encased in a metal tube or can and again sealed with epoxy.

with all the above case styles available in both Axial and Radial Leads.

Film Capacitors which use polystyrene, polycarbonate or Teflon as their

dielectrics are sometimes called “Plastic capacitors”. The construction

of plastic film capacitors is similar to that for paper film capacitors but

use a plastic film instead of paper.

The main advantage of plastic film types of capacitor compared to

impregnated-paper types is that they operate well under conditions of high

temperature, have smaller tolerances, a very long service life and high

reliability. Examples of film capacitors are the rectangular metalised film

and cylindrical film & foil types as shown below.

Radial Lead Type

radial lead capacitor

radial lead capacitor

Axial Lead Type

metalised foil capacitor

The film and foil types of capacitor are made from long thin strips of thin

metal foil with the dielectric material sandwiched together which are wound

into a tight roll and then sealed in paper or metal tubes.

film capacitor type

metalised foil capacitor

The film and foil types of capacitor are made from long thin strips of thin

metal foil with the dielectric material sandwiched together which are wound

into a tight roll and then sealed in paper or metal tubes.

film capacitor type

|

|

|

These film types require a much thicker dielectric film to reduce the risk

of tears or punctures in the film, and is therefore more suited to lower

capacitance values and larger case sizes.

|

|

Metalised foil capacitors have the conductive film metalised sprayed

directly onto each side of the dielectric which gives the capacitor self

-healing properties and can therefore use much thinner dielectric films.

This allows for higher capacitance values and smaller case sizes for a given

capacitance. Film and foil capacitors are generally used for higher power

and more precise applications.

Ceramic Types of Capacitor

Ceramic Capacitors or Disc Capacitors as they are generally called, are made

by coating two sides of a small porcelain or ceramic disc with silver and

are then stacked together to make a capacitor. For very low capacitance

values a single ceramic disc of about 3-6mm is used. Ceramic capacitors have

a high dielectric constant (High-K) and are available so that relatively

high capacitance’s can be obtained in a small physical size.

ceramic construction

|

|

|

They exhibit large non-linear changes in capacitance against temperature and

as a result are used as de-coupling or by-pass capacitors as they are also

non-polarized devices. Ceramic capacitors have values ranging from a few

picofarads to one or two microfarads, ( μF ) but their voltage ratings are

generally quite low.

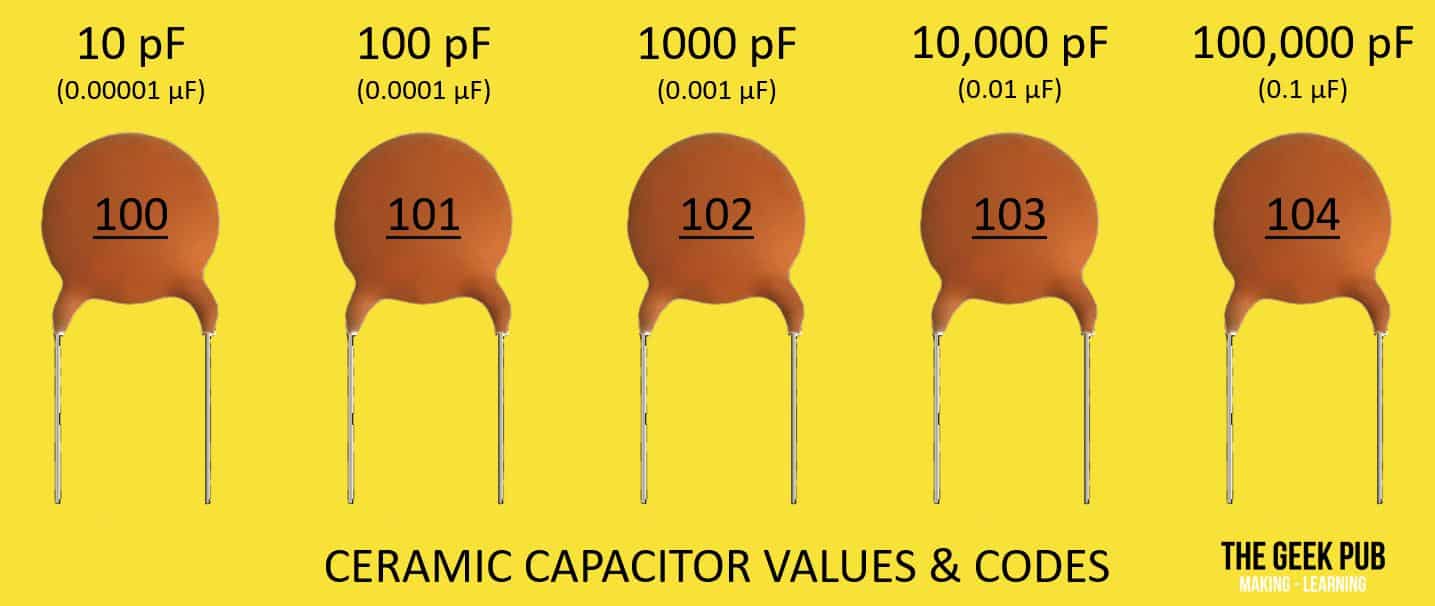

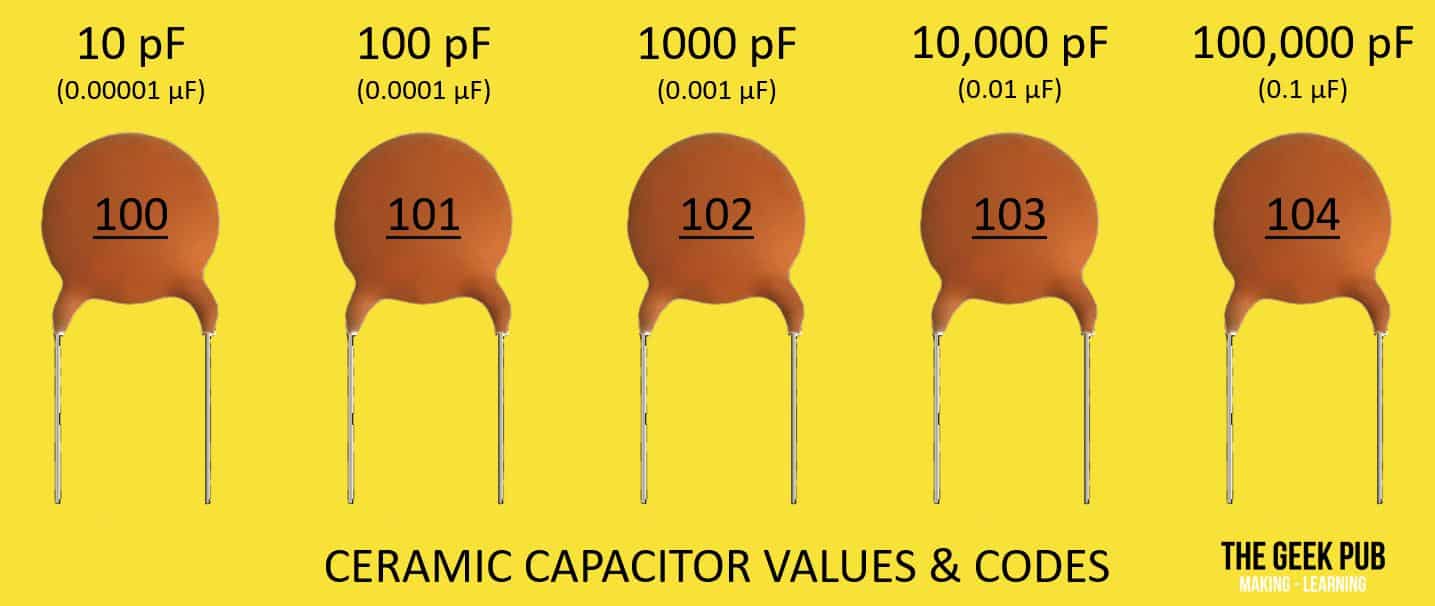

Ceramic types of capacitors generally have a 3-digit code printed onto their

body to identify their capacitance value in pico-farads.

|

|

Let’s break that 3 digit code!

The first two digits are the capacitance value in pF and the third digit is

simply a multiplier. This is where you need a good memory, or the calculator!

The multiplier is always a number between zero and six. If you find a larger

number than six, it is not using the standard numbering scheme, or it may not

even be a capacitor.

Ceramic Capacitor Multipliers

Here’s a simple table of the multipliers you can use to do this calculation in

your head:

Let’s break that 3 digit code!

The first two digits are the capacitance value in pF and the third digit is

simply a multiplier. This is where you need a good memory, or the calculator!

The multiplier is always a number between zero and six. If you find a larger

number than six, it is not using the standard numbering scheme, or it may not

even be a capacitor.

Ceramic Capacitor Multipliers

Here’s a simple table of the multipliers you can use to do this calculation in

your head:

- multiply by 1

- multiply by 10

- multiply by 100

- multiply by 1000

- multiply by 10,000

- multiply by 100,000

- multiply by 1,000,000

Generally the first two digits indicate the capacitors value and the third digit

indicates the number of zero’s to be added. For example, a ceramic disc

capacitor with the markings 103 would indicate 10 and 3 zero’s in pico-farads

which is equivalent to 10,000 pF or 10nF.

Likewise, the digits 104 would indicate 10 and 4 zero’s in pico-farads

which is equivalent to 100,000 pF or 100nF and so on. So on the image of the

ceramic capacitor above the numbers 154 indicate 15 and 4 zero’s in pico

-farads which is equivalent to 150,000 pF or 150nF or 0.15μF. Letter codes

are sometimes used to indicate their tolerance value such as: J = 5%, K =

10% or M = 20% etc.

Electrolytic Types of Capacitor

Electrolytic Capacitors are generally used when very large capacitance

values are required. Here instead of using a very thin metallic film layer

for one of the electrodes, a semi-liquid electrolyte solution in the form of

a jelly or paste is used which serves as the second electrode (usually the

cathode).

The dielectric is a very thin layer of oxide which is grown electro

-chemically in production with the thickness of the film being less than ten

microns. This insulating layer is so thin that it is possible to make

capacitors with a large value of capacitance for a small physical size as

the distance between the plates, d is very small.

electrolytic

|

|

|

The majority of electrolytic types of capacitors are Polarised, that is the

DC voltage applied to the capacitor terminals must be of the correct

polarity, i.e. positive to the positive terminal and negative to the

negative terminal as an incorrect polarisation will break down the

insulating oxide layer and permanent damage may result.

|

|

Electrolytic Capacitor

|

All polarised electrolytic capacitors have their polarity clearly marked

with a negative sign to indicate the negative terminal and this polarity

must be followed.

Electrolytic Capacitors are generally used in DC power supply circuits due

to their large capacitance’s and small size to help reduce the ripple

voltage or for coupling and decoupling applications. One main disadvantage

of electrolytic capacitors is their relatively low voltage rating and due to

the polarisation of electrolytic capacitors, it follows then that they must

not be used on AC supplies. Electrolytic’s generally come in two basic

forms; Aluminium Electrolytic Capacitors and Tantalum Electrolytic

Capacitors.

Electrolytic Capacitor

aluminium electrolytic construction

aluminium electrolytic construction

1. Aluminium Electrolytic Types of Capacitor

There are basically two types of Aluminium Electrolytic Capacitor, the plain

foil type and the etched foil type. The thickness of the aluminium oxide

film and high breakdown voltage give these capacitors very high capacitance

values for their size.

The foil plates of the capacitor are anodized with a DC current. This

anodizing process sets up the polarity of the plate material and determines

which side of the plate is positive and which side is negative.

The etched foil type differs from the plain foil type in that the aluminium

oxide on the anode and cathode foils has been chemically etched to increase

its surface area and permittivity. This gives a smaller sized capacitor

than

a plain foil type of equivalent value but has the disadvantage of not being

able to withstand high DC currents compared to the plain type. Also their

tolerance range is quite large at up to 20%. Typical values of capacitance

for an aluminium electrolytic capacitor range from 1uF up to 47,000uF.

Etched foil electrolytic’s are best used in coupling, DC blocking and by

-pass circuits while plain foil types are better suited as smoothing

capacitors in power supplies. But aluminium electrolytic’s are “polarised”

devices so reversing the applied voltage on the leads will cause the insulating

layer within the capacitor to become destroyed along with the capacitor.

However, the electrolyte used within the capacitor helps heal a damaged plate

if the damage is small.

Since the electrolyte has the properties to self-heal a damaged plate, it also

has the ability to re-anodize the foil plate. As the anodizing process can be

reversed, the electrolyte has the ability to remove the oxide coating from the

foil as would happen if the capacitor was connected with a reverse polarity.

Since the electrolyte has the ability to conduct electricity, if the aluminium

oxide layer was removed or destroyed, the capacitor would allow current to pass

from one plate to the other destroying the capacitor, “so be aware”.

2. Tantalum Electrolytic Types of Capacitor

Tantalum Electrolytic Capacitors and Tantalum Beads, are available in both

wet (foil) and dry (solid) electrolytic types with the dry or solid tantalum

being the most common. Solid tantalum capacitors use manganese dioxide as

their second terminal and are physically smaller than the equivalent

aluminium capacitors.

The dielectric properties of tantalum oxide is also much better than those

of aluminium oxide giving a lower leakage currents and better capacitance

stability which makes them suitable for use in blocking, by-passing,

decoupling, filtering and timing applications.

Also, Tantalum Capacitors although polarised, can tolerate being connected

to a reverse voltage much more easily than the aluminium types but are rated

at much lower working voltages. Solid tantalum capacitors are usually used

in circuits where the AC voltage is small compared to the DC voltage.

However, some tantalum capacitor types contain two capacitors in-one,

connected negative-to-negative to form a “non-polarised” capacitor for

use in low voltage AC circuits as a non-polarised device. Generally, the

positive lead is identified on the capacitor body by a polarity mark, with

the body of a tantalum bead capacitor being an oval geometrical shape.

Typical values of capacitance range from 47nF to 470uF.

Aluminium & Tantalum Electrolytic Capacitor

|  Electrolytic’s are widely used capacitors due to their low cost and small

size but there are three easy ways to destroy an electrolytic capacitor:

Electrolytic’s are widely used capacitors due to their low cost and small

size but there are three easy ways to destroy an electrolytic capacitor:

- Over-voltage – excessive voltage will cause current to leak through

the dielectric resulting in a short circuit condition.

- Reversed Polarity – reverse voltage will cause self-destruction of

the oxide layer and failure.

- Over Temperature – excessive heat dries out the electrolytic and

shortens the life of an electrolytic capacitor.

In the next tutorial about Capacitors, we will look at some of the main

characteristics to show that there is more to the Capacitor than just

voltage and capacitance.

previousPrevious

Introduction to Capacitors

Next

Capacitor Characteristics

next

|

variable capacitor symbol

As well as the continuously variable types of capacitor, preset type

variable capacitors are also available called Trimmers. These are generally

small devices that can be adjusted or “pre-set” to a particular

capacitance value with the aid of a small screwdriver and are available in

very small capacitance’s of 500pF or less and are non-polarized.

variable capacitor symbol

As well as the continuously variable types of capacitor, preset type

variable capacitors are also available called Trimmers. These are generally

small devices that can be adjusted or “pre-set” to a particular

capacitance value with the aid of a small screwdriver and are available in

very small capacitance’s of 500pF or less and are non-polarized.

radial lead capacitor

radial lead capacitor

metalised foil capacitor

The film and foil types of capacitor are made from long thin strips of thin

metal foil with the dielectric material sandwiched together which are wound

into a tight roll and then sealed in paper or metal tubes.

film capacitor type

metalised foil capacitor

The film and foil types of capacitor are made from long thin strips of thin

metal foil with the dielectric material sandwiched together which are wound

into a tight roll and then sealed in paper or metal tubes.

film capacitor type

Let’s break that 3 digit code!

The first two digits are the capacitance value in pF and the third digit is

simply a multiplier. This is where you need a good memory, or the calculator!

The multiplier is always a number between zero and six. If you find a larger

number than six, it is not using the standard numbering scheme, or it may not

even be a capacitor.

Ceramic Capacitor Multipliers

Here’s a simple table of the multipliers you can use to do this calculation in

your head:

Let’s break that 3 digit code!

The first two digits are the capacitance value in pF and the third digit is

simply a multiplier. This is where you need a good memory, or the calculator!

The multiplier is always a number between zero and six. If you find a larger

number than six, it is not using the standard numbering scheme, or it may not

even be a capacitor.

Ceramic Capacitor Multipliers

Here’s a simple table of the multipliers you can use to do this calculation in

your head:

aluminium electrolytic construction

aluminium electrolytic construction

Electrolytic’s are widely used capacitors due to their low cost and small

size but there are three easy ways to destroy an electrolytic capacitor:

Electrolytic’s are widely used capacitors due to their low cost and small

size but there are three easy ways to destroy an electrolytic capacitor: